If you manufacture corrugated paperboard, eliminating warp is a familiar challenge. There are a number of factors that contribute to warp and an equal number of techniques for reducing it, but the ability to completely eradicate warp still remains a mystery. In this post, we provide an overview of paperboard warp and provide several options for decreasing its occurrence. We have also included here, the links to additional articles on corrugator alignment that may be of benefit to you and your team:

The Importance of Machine Alignment – 3-Part Corrugator Series

Routine Corrugator Inspections Key to Identifying Potential Issues

Why is Eliminating Warp Still Such a Mystery?

What is Warp?

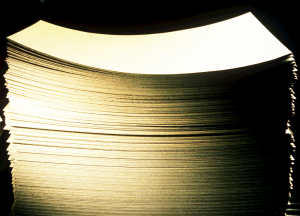

A simple definition for warp is “. . . to become bent or twisted out of shape, typically as a result of the effects of heat or dampness”. In the corrugated paperboard arena, this definition of warp applies to one of the most common problems that these manufacturers face – producing bent or twisted corrugated board that results in excessive scrap, waste, and reduced production rates.

What Causes Warp?

There are several main causes of warp:

- Moisture imbalance between the top and bottom liners

- Tension imbalance between the top and bottom liners

- Corrugator component misalignment

Moisture Imbalance

In the process of applying adhesive to the liners, there should be a delicate balance of heat and bonding between the layers with the adhesive consistently applied to the flute tips. Exposure to high humidity, applying excessive adhesive, inconsistent adhesive application and improper glue roll to paper speeds will all cause moisture imbalance which in turn leads to warp in the cross-machine direction. Moisture related warp defects will display as:

Eliminating warp continues to be a challenge faced by many corrugated board manufacturers

Up Warp – board bows up (convex)

Down Warp – board bows down (concave)

S Warp – board bows up on one corner and bows down on the opposite corner

Diagonal or Twist Warp – board curves along the diagonal of the sheet

Techniques for reducing moisture related warp include:

- Increase corrugator speed (if possible)

- Adjust web and liner wrap – either reduce double back wrap or increase single face wrap

- Increase adhesive settings

- Equalize the temperature across the width of the sheet by inspecting for parallel misalignment between the preheater drums and wrap arms, and make proper alignment adjustments so that they are parallel one another

Tension Issues

In any process line that is web fed, tension problems can occur and corrugating lines are no exception. A difference in tension between the top and bottom of the sheet can result in machine direction warp – also known as end-to-end up warp or end-to-end down warp. Conditions that can attribute to this tension related warp are:

- Preheaters turning improperly (or not at all)

- Rolls not turning freely

- Inadequately functioning roll stand brakes

- Poorly maintained web guides

- Excessive drag in the hot plate section

- Cross tension due to uneven draw in belts

- Significant parallel misalignment between units within a specific corrugator section

There are several methods for improving tension related warp issues such as:

- Adjust wrap when liners do not create enough drag on the preheaters

- Perform quarterly inspections and maintenance of splicers and other units to ensure bearings and rolls are moving freely

- Perform regular inspections and maintenance on braking systems to check for brake and caliper wear

- Perform weekly inspections and cleansing of web guides – vacuum guides/holes can become clogged creating less vacuum and less tension

- Perform wear inspections of tension roll covers – worn or smooth covers will not add enough drag to the web

- Perform regular inspections and maintenance of hot plates

- Inspect for misalignment within all components and rolls and make necessary adjustments so that they are parallel to one another

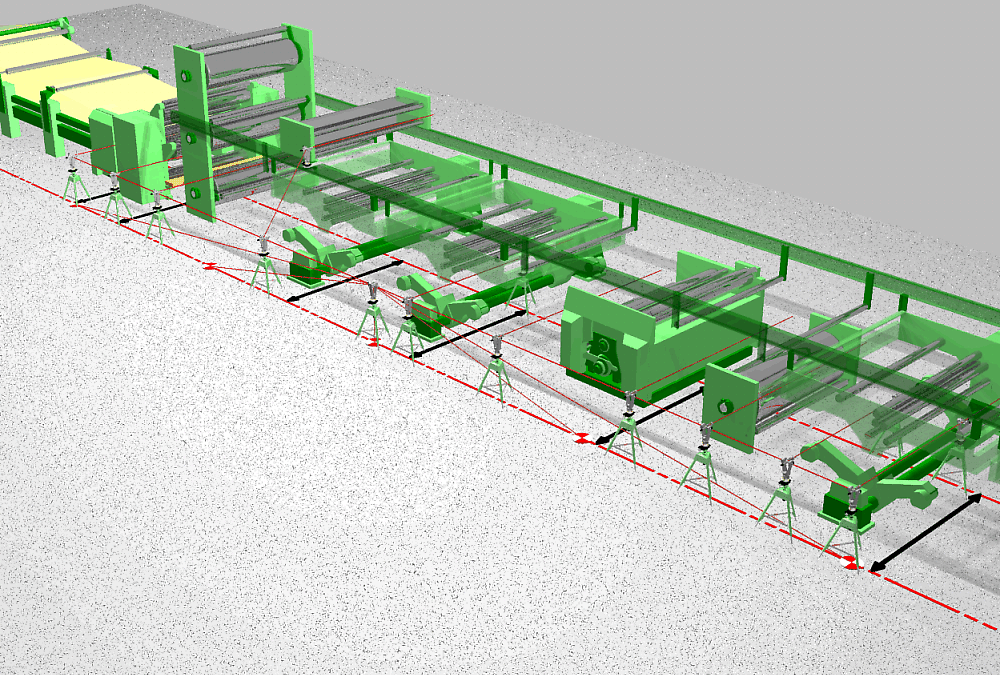

Corrugator Component Misalignment

When corrugator components are not aligned parallel to one another, product variations and inconsistencies can be introduced, which can lead to warp issues. Precision alignment of corrugator components helps reduce issues associated with the following:

- Paper stresses

- Tension issues

- Heat variations across the product width

- Wrinkles

Conclusion

Warp has always been an issue in the manufacturing of corrugated box board – and as outlined in this post, there may be a number of factors that contribute to this problem. However, being aware of these factors and eliminating them one at a time, gives you a fighting chance against this common nuisance.

If you would like more information on ways to reduce and control warp, please contact us – we would be happy to assist you. For a site visit by an OASIS representative, please contact the OASIS Service Center nearest you.