One of the nation’s leading producers of rotogravure printed flexible packaging required alignment of the chill rolls of one of their printing presses. Additionally, they had developed severe wrinkling through the foil section of their Rotomec coater/laminator.

One of the nation’s leading producers of rotogravure printed flexible packaging required alignment of the chill rolls of one of their printing presses. Additionally, they had developed severe wrinkling through the foil section of their Rotomec coater/laminator.

The printing press is a 10-color Rotogravure printing press with in-line lamination capability. The materials produced on this machine are printed and/or laminated using various films and papers to produce healthcare and food packaging materials. When this facility noticed web weave issues and wrinkles throughout the machine causing register issues and excessive waste, they began replacing their chill rolls, which are chilled with water to cool the hot material that is webbed around the rolls.

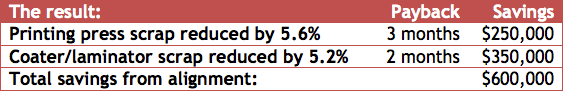

OASIS was contracted to survey the line and provide optical support to the mill’s in-house team as they replaced the chill rolls. While doing the survey, measurements showed that the entire line was grossly misaligned. As a result, the facility expanded the scope of duties to include complete assessment and press realignment. Ten separate stations involving more than 500 rolls were involved in the alignment project.

Their Triplex Rotogravure laminator is used to apply specialty coatings on film, foil or paper. This machine can also combine up to three roll-fed materials to make a single 3-layer structure. They developed severe wrinkles through the foil section, coating skipping, baggy edges and tracking issues that were costing this company approximately 5% of scheduled run time. The alignment project that ensued required verification of the existing baseline, a complete machine survey and the realignment of the entire coater/laminator – a total of 237 rolls.

Correct alignment will directly affect the runability of products through equipment. Increased scrap and reduced speed due to misalignment directly impact the cost of production and thus the bottom line. The best way to identify when alignment is needed is to trend scrap rates and machine conditions. Alignment, if done at set intervals based on historical data, lowers costs and improves quality.