Competition in the paper industry can be intense – and getting the most from your paper machine is crucial. This can be tough with many paper companies running older machines that are being pushed to their limits. To remain competitive, paper companies are often upgrading (modifying, rebuilding and/or adding components to) their older machines in order to boost production and improve quality.

The precision alignment of these components is a critical factor in improving the performance of your paper machine.

In this first of a series of posts on the precision alignment of paper machines, we discuss the importance of alignment during forming section upgrades and provide an overview of alignment methodology. In future posts we will discuss alignment of components in other areas of your paper machine and also provide a guide for tolerances throughout the machine.

Why is Wet End Alignment so Important?

The proper alignment of your wet end is essential to your papermaking process – especially if you are upgrading components. Often, precision alignment of the wet end will lead to:

♦ Improved dewatering efficiency

♦ Decreased wear of table elements and forming boards

♦ Improved wire tracking

♦ Extended wire life

♦ Dry line evenness

♦ Improved product quality

♦ Greater ROI from the upgrade project

Wet End Alignment Methods

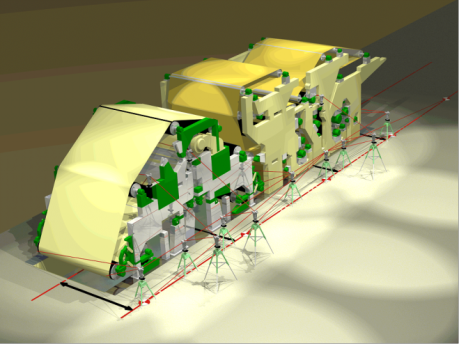

Using optical instruments or 3D metrology tools, an alignment specialist will perform a survey of the components in order to establish the best overall centerline of the machine.

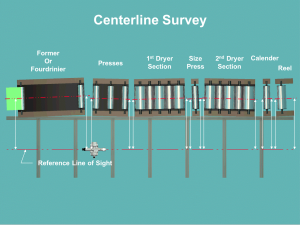

Prior to any upgrade effort, it is highly recommended that a current centerline survey of the entire machine be performed for either the verification of an existing baseline or, if deemed necessary, the installation of a new one. This overall machine baseline (offset centerline representation) will then become a reliable reference for aligning all components of the forming section to be upgraded, as well as for all future alignment efforts throughout the machine.

In this first step, using either optical instruments or 3D metrology tooling such as a laser tracker, an alignment specialist will obtain comparative dimensions from a beginning offset reference line (typically an existing baseline or a temporary reference line of sight in the tending or operator side aisle of the machine) to the centerline of various components throughout the length of the machine (former through reel). These dimensions are then analyzed to determine whether or not the beginning reference line is a suitable representation of the overall machine centerline. Once a suitable reference line is determined that adequately represents the best overall machine centerline, permanent offset baseline references are then established by recording the as-built locations of existing and/or newly installed baseline monuments relative to the offset machine centerline reference line.

The next important step for the precision alignment of the wet end upgrade project is to survey the current alignment condition of the forming section components to be upgraded along with any adjacent existing components that will not be part of the project. This survey allows for any potential misalignment of the wet end to be addressed during the overall scope of the project, rather than later when the adjustments or repairs will require additional downtime and costs.

In future posts we will provide more on alignment techniques in other areas of your paper machine including press, dryer, calender and reel sections. If you are planning an upgrade and would like to discuss your alignment needs or if you would like a site visit to your mill, please contact us.