Whether we are performing an alignment inspection on the components of a paper machine or measuring bolt holes on the wing of an airplane, highly accurate, repeatable, precision measurement is at the foundation of every job we do. Here we have included links to several articles on topics that we certainly find interesting and that may be of benefit to you and your team:

The Versatility of Modern Metrology Devices

Podcast: 3-Dimensional Metrology’s Impact on Manufacturing

Repeatability in Measurement – Why is it Important?

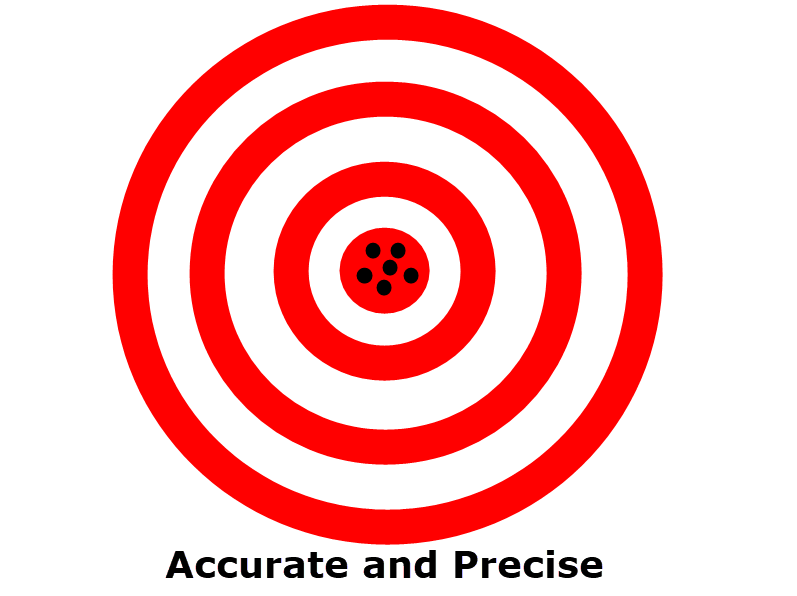

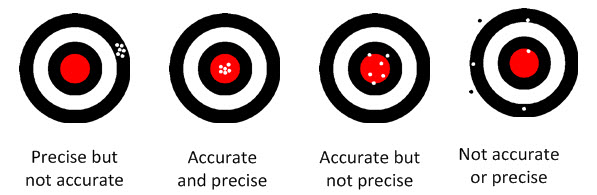

When speaking of measurements, accuracy is the topic that is most often discussed. But in fact, there is something equally important that is often overlooked – repeatability, otherwise known as precision. When measuring in industrial conditions, a service company can take alignment measurements with less than perfect instruments and achieve a specification of accuracy. Yet, unless the measurements can be repeated, you are actually not precise at all.

There are many factors that come into play that affect the ability to repeat measurements including poor instrument quality, instruments out of calibration, inadequate methods of data collection and operator inefficiency or inexperience.

Calibration is important because it guarantees that an instrument is capable of measuring to the specifications for which it is rated. Many instruments lose their calibration, and hence their accuracy, over time, therefore it is necessary to recalibrate them on a regular basis. If the calibration process is designed properly, the results will be traceable to standards of measurement and length artifacts. Examples of these artifacts are kept at internationally renowned laboratories such as NIST, NPL, and NRC. In optical instrument calibration, the basic properties of parallel light rays focused at infinity are used to calibrate optical instruments for several parameters. For 3-dimensional metrology tools, volumetric compensations are performed to adjust the kinematic model of the device for its current measurement state.

Why is repeatability so important? In order to refine a process that is dependent on alignment, whether it be a web driven process, a machining process, an assembly process, or a stamping process, the finished product’s quality will be affected by variances. Variances and irregularity defects are generally not desirable. If misalignment or dimensional errors cannot be removed because different readings or conditions are detected every time measurements are inspected, quality cannot be improved. One could argue that it is better to be precise, or repeatable, rather than accurate.

Another factor can be the methods employed by the operator. A good optical instrument operator with accurate instruments can make measurements repeatable. However, if the operator’s techniques are flawed, or the measurement technician is not as skilled, then repeatable results may not occur. The variations in measurements due to operator error when a measurement system is accurate and precise is called reproducibility.

The same goes for 3D Metrology: if you do not have the right techniques or are not using the right methods, you might have an instrument with good specifications, but your measurements may not be reproducible due to operator inefficiency.

In closing, remember: operator efficiency is just as important as instrument accuracy and precision. This is why training is the most important determining factor to ensure you are getting precise measurements. Although a few select post graduate institutions are lucky enough to have programs dedicated to dimensional metrology, the practical aspect of ensuring repeatability and reproducibility with accurate instruments is not taught in schools. User courses provided by instrument manufacturers and metrology software training can guide engineers and technicians in the right direction, but only in-house training and on-the-job training can properly prepare metrologists. OASIS is committed to quality, that is why we strive to train and prepare our employees for the countless processes and types of measurements they will face in their everyday work and to be the very best at what they do.

If you would like to discuss how precision measurement can help improve efficiency at your location, please contact us – an OASIS representative would be happy to assist you.