Resources

The time is now to be informed.

We strongly believe that an informed customer achieves the greatest success.

ALL

PRECISION MEASUREMENT

MACHINE ALIGNMENT

MECHANICAL SERVICES

ALL

PRECISION MEASUREMENT

MACHINE ALIGNMENT

MECHANICAL SERVICES

In-Place Machining Company Acquires WL3 Solutions, LLC

Addition of 3D Metrology Expert Reinforces Commitment to Providing Comprehensive Industrial Services to Commercial and Defense Aerospace and Shipbuilding Customers. In-Place Machine Company, LLC (IPM) is pleased to announce the acquisition of WL3 Solutions (WL3) as...

In-Place Machining Company (IPM) Streamlines Operations with Newly Expanded Blue Ash, Ohio Facility

Consolidation of IPM, Exact Metrology, and OASIS Alignment Services in single location strengthens synergy of divisions for enhanced service to aerospace, power generation, heavy manufacturing and other industries. In-Place Machining Company (IPM) is pleased to...

Webinar Replay – Paper Machine Alignment: Methods, Tolerances & Tooling

In the pulp & paper industry the competition can be fierce. In order to remain competitive, paper machines must run at optimum performance levels – even when being pushed to their limits. Having a solid understanding of how component alignment and tolerances...

In-Place Machining Company Adds Pulp & Paper Roll Repair Expert Western Machine Works, LLC to Machining Division

Strategic Partnership Expands Industrial Machining and Repair Capabilities and Strengthens Commitment to Providing Customer Service Excellence March 7, 2023 | Milwaukee, WI – In-Place Machine Company, LLC (IPM) is pleased to announce the acquisition of...

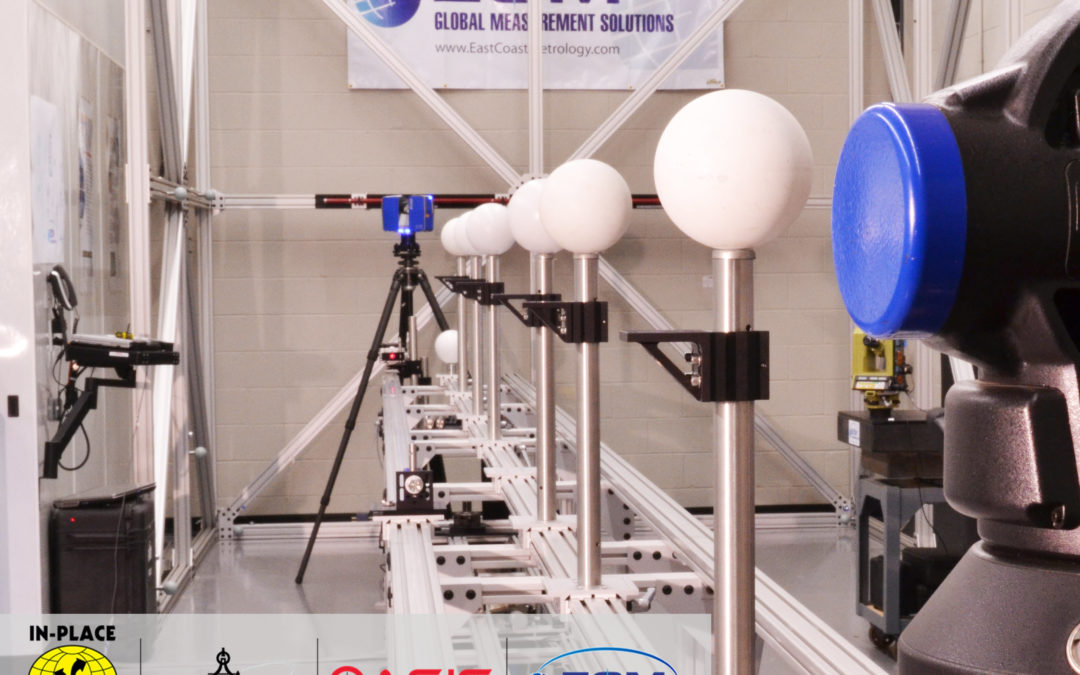

East Coast Metrology Joins OASIS & Exact Metrology in the IPM Measurement & Alignment Services Group

OASIS is very excited to have East Coast Metrology (ECM) join us in the Measurement & Alignment Services Group of In-Place Machining Company. By combining the metrology and calibration capabilities of ECM with the 3D scanning and alignment services of Exact...

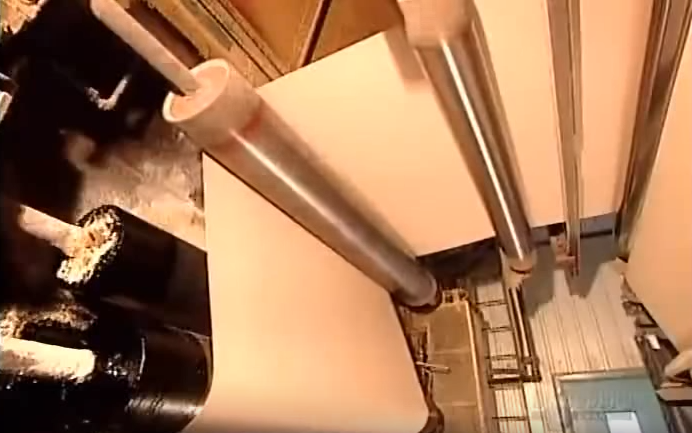

Greenpac Mill Benefits From Fast Response & OASIS Mechanical Capabilities

When Greenpac Mill in Niagara Falls, NY, found that they were going to be shorthanded during a recent outage, they reached out to OASIS for assistance with changing two drive side dryer can bearings. OASIS regularly performs dryer bearing changes with the use of...

OASIS Announces Exciting Organizational Changes

OASIS Alignment Services: A Division of In-Place Machining Company Announces Organizational Changes Steve Pepin promoted to Sales Director – Measurement & Alignment Services, In-Place Machining Company Ted Grimbilas promoted to Northeast Regional Manager,...

What is Metrology Anyway?

As a metrology services provider, we can sometimes take for granted that everyone else knows what we are talking about when we discuss our “metrology services”. In this post, we provide a brief definition overview of metrology. In future posts we will delve deeper...

Precision Alignment Can Help Roofing Manufacturers Avoid Costly Issues

Roofing production lines, like most large manufacturing process lines, rely on rolls, gears, motors, chains, drums, and cutters that must all work in unison to produce a quality finished product. Precision alignment - meaning level to earth and perpendicular or square...

Laser Trackers Help Reduce AOG (Aircraft On Ground) Time Due to Bird Strikes

As long as birds and airplanes share the same space in the sky, there will continue to be bird strikes causing damage to aircraft. Luckily for the airlines (not so much the birds), with advanced metrology tools such as laser trackers and coordinate measuring arms,...