In this first of a series of posts on 3D metrology solutions for turbo machinery, we provide an overview of metrology applications and some of the benefits of using a service provider equipped with 3D metrology tooling. In upcoming posts we will delve deeper into solutions for specific types of turbines used to generate power.

Why 3D Metrology for Turbine Alignment?

When turbine components are misaligned, production and efficiency are at risk. This is true whether working with gas, steam, hydro, wind or nuclear turbo machinery. A turbine with all components properly aligned, helps to keep a power generating or processing plant operating at full capacity.

Traditional alignment methods for inspecting turbines typically involve plumb bobs, piano wires, micrometers, optical tools and other 2D alignment technologies. These methods are often complicated, time consuming and prone to human error.

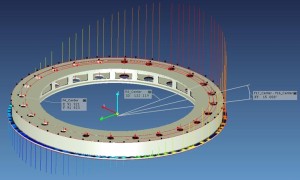

With today’s advanced measurement technologies, such as laser trackers, portable measuring arms and laser scanners, metrology engineers can provide alignment surveys and measurements with greater efficiency than more traditional methods. These portable, highly accurate metrology systems gather and interpret large volumes of data quickly and accurately and data is presented instantly via 3D metrology software.

3D Metrology Applications

Innovative metrology devices can do more than just replace traditional alignment methods. Metrology engineers can now measure position, perpendicularity, parallelism, angularity, surface profile, line profile, straightness, flatness, circularity, cylindricity, symmetry, concentricity and datum qualification. Some of the more common applications for the power generation industries include:

♦ Casings Inspections & Alignment

♦ Wicket Gate Stay and Discharge Rings Inspections & Alignment

♦ Runner Inspections

♦ Generator Alignment -Keybars, Stators & Main Bearings

♦ Horizontal Machine Bearings Alignment

♦ Main Shaft Inspection and Alignment

♦ Case to Case Alignment – With or Without Rotating Assemblies

♦ Tops-off Alignment

♦ Installation Pads Alignment & Verification

♦ Scroll Case Alignment

♦ Dynamic Load & Thermal Growth Studies & Verifications

♦ Foundation Stability Studies

♦ Pipe Strain Effects Analysis

♦ Reactor Face Inspections

Benefits of 3D Metrology Solutions

The benefits of using a 3D metrology service provider equipped with portable coordinate metrology devices include:

♦ Alignment Surveys & Dimensional Measurement with Greater Efficiency

♦ Quick Setup & Reverse Engineering Measurements of Existing Installations

♦ Precise and Accurate Dimensional Metrology in Less than Perfect Environments such as Nuclear Reactor Vaults, Hydro Installations, Steam Turbine Halls and More

♦ Thermal Growth & Load Studies Completed over Warm-up & Cool-down Periods

♦ Data Collected in Hours instead of Days – Significantly Reduce Outage Downtime

♦ High Degree of Accuracy and Repeatability

♦ Reports Created Onsite and in Real Time

In an upcoming post in this series, we will dig deeper into precision measurement and alignment solutions for the hydro power industry. For more information on 3D Metrology Solutions for power generation facilities, please contact us at customerservice@oasisalignment.com.