Bowed Roll Alignment

Bowed rolls can often be found in several areas of a paper machine and on most converting machines. The main function of bowed (or spreader) rolls in web production equipment is to spread the web and/or keep the web flat, as it runs through the processes. The spreading that occurs when bowed rolls are in place help to widen the web, separate slit webs prior to winding and help reduce wrinkling, creases and foldovers.

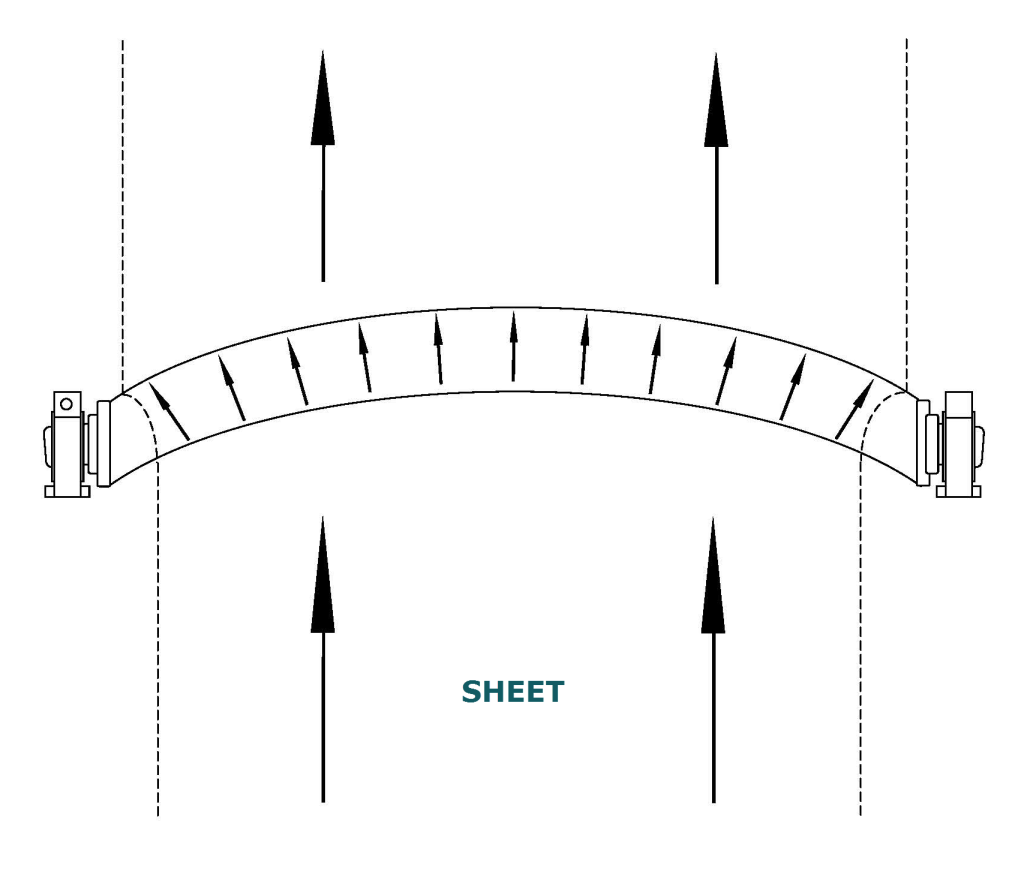

In the paper making process, bowed rolls are most commonly used to spread the paper sheet evenly from the center out. This is accomplished by positioning the bow toward the direction the sheet is traveling. As the bowed roll turns, the area of cover that contacts the sheet expands as it moves from the inner radius of the bow to the larger outer radius. A sheet that is moving over a correctly aligned and positioned bow will spread with the roll cover.

Bowed rolls consist of a metal or a flexible rubber cover over several bearing assemblies. The bearings are mounted on a prebowed axle. Each end of the axle is held in a bearing mounted in a stand. Spreader rolls are typically prebowed and the degree of the bow is not adjustable in the field. The roll axle can be rotated in the stand bearings to change the position of the bow in relation to the sheet.

The amount of bow is important because too little will reduce the effectiveness of the spreader and tool much will also reduce spreading and may even cause the very wrinkles you are trying to remove. Additionally, the roll cover must be “grippy” because traction is vital for the spreading function. In some high speed applications, the cover may actually need grooving to achieve this.

Proper bowed roll alignment helps to reduce uneven web tension, wrinkles and sheet breaks

A bowed roll can be used in the following areas of a paper machine:

- First Press – keeps the felt weave open and the seam straight

- Second Press – keeps the felt weave open without excessive tension

- Third Press – preserves the nap of the finishing felt

- Dryer – regulates shrinkage rate and distributes tension across sheet

- Yankee Dryer – helps to reduce sheet wrinkles

- Size Press – eliminates wet wrinkles caused by saturation

- Calender – spreads the sheet evenly to prevent calender cuts

- Reel – prevents wrinkles and tightens slack edges

Importance of Proper Alignment

As with any roll in a web production line, proper alignment of bowed rolls is key to running at optimum speeds and efficiency. Bowed rolls must not only be pointing in the right direction, but it is critical that the bow be centered on the web path in order to achieve equal spreading and tension on both the drive side and tending side of the machine. If the bowed roll is not centered on the machine, product will not track correctly, causing uneven tension. Uneven tension leads to issues such as wrinkles and sheet break.

Aligning Bowed Rolls

When inspecting traditional straight rolls with optical tooling, alignment technicians typically take roll readings at equal distances in from the mounting bearings or the ends of the roll.

When inspecting a bowed roll, it is very important that the roll is properly aligned ensuring that the bow is symmetrical to the web path. One of the ways to ensure proper equipment alignment involves inspecting the ends of the roll for indication of web edge. Often the ends of the roll will be discolored and/or show surface wear where the edges of the web run. Once you determine where the edges are, optical readings can be taken equidistance from those indicators to ensure that the aligned bow is symmetrical about the web path.

Another inspection option is to place a mark on the bowed roll to indicate the center of the web. This can be done by placing a piece of tape on the roll surface and marking the tape. Next, instead of measuring IN from the ends of the roll, alignment technicians will measure OUT from the centerline of the web path mark on the roll. This process insures that the roll is aligned to the web path and not to the roll mounting surfaces.

Note that aligning a bowed roll is quite different than the actual positioning of the bow in the web path which is typically done by the machine tender.

If you would like more information on bowed roll alignment, please contact us. We would be happy to provide a site visit to your facility to discuss your needs.