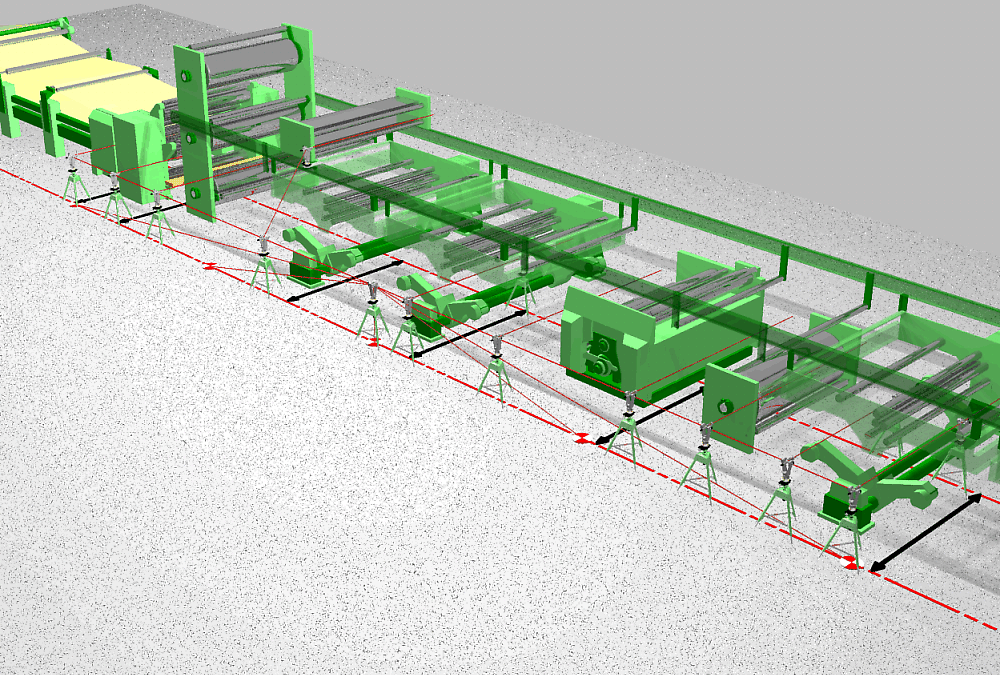

As we stated recently in a previous post, we are providing the corrugated industry with tips to help them increase efficiency in order to keep up with the demand for the corrugated boxes needed by online shoppers. In Part One of the Importance of Machine Alignment: Corrugators, we provided a client example of waste due to misalignment. Here in Part Two, we discuss what to look for to determine misalignment, and the need for alignment services.

The Signs and Symptoms of Misalignment within Your Corrugator

How do you know if misalignment currently exists within your corrugator? What type of indicators might you come across? The following list identifies some of those indicators and how they relate to misalignment:

- Board Quality – If your final product exhibits significant warp issues or delamination, then there is a good chance parallel misalignment exists within and around your preheater drums and wrap arms.

- Crushing – If the board and flutes are exhibiting crushing, then there is a good chance there are severe elevation deviations within the hot plates of the double backer.

- Visible Baggy Edges – A baggy edge with the product is a sure sign that misalignment exists, specifically in and around those rollers.

- Web Breaks – If frequent web breaks occur, especially in the same area, then misalignment may exist. This can commonly occur with missed splices at the roll stands and splicers.

- A Reduction in Operating Speeds – If a decrease in operating speeds is trending, it may be compensating for misalignment. The faster rotating machinery operates, the more critical it is for rolls to be parallel.

- Increased bearing and coupling failures – “Somewhere between 50 and 70 percent of all rotating equipment failure is caused by misalignment”. Worn bearings will effect alignment, but worse, can affect the conditions of the roll journals and require costly repairs and replacement.” (quoted numbers taken from an article in Materials Evaluation/June 1994)

- Wrap arm gear timing – If slippage or large jumps are observed with the wrap arms as they rotate around the drum, this indicates a need to correct the worn hardware or tighten loose couplings at the cross shaft. Continued operation under these conditions will have adverse effects on the hardware and product quality.

NOTE: It should be noted that other factors, aside from misalignment, may also contribute to the issues listed above. In our next post, we’ll discuss how machine alignment and tune-ups work hand in hand.