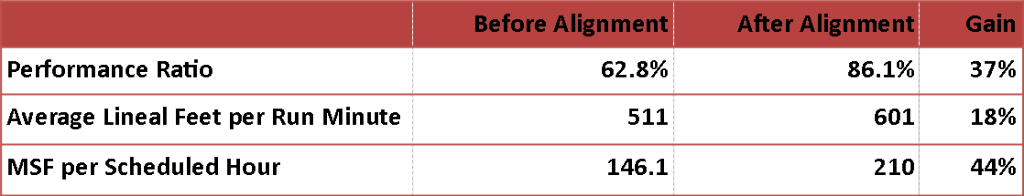

One of the largest packaging facilities in the Midwest requested an alignment survey of the double backer through the wet end of their corrugator. During the initial survey, OASIS found significant misalignment conditions. After a complete realignment of the machine, this facility has seen a marked improvement in production and supplied the following impressive data:

The site manager offered the following:

“The performance of the machine continues to improve as operator skill improves. We have had shifts that ran at 98% uptime and 268 MSF/hr. This improvement has had a positive impact on quality, waste and employee morale.”