In this first of a two-part series on the importance of alignment in the reel section of a paper machine, we provide an overview of reel section alignment, the issues you will see when components are misaligned and the benefits of precision alignment. In part two, we will delve further into alignment of the reel drum, reel rails, primary arms, secondary arms and spools.

The paper machine reel is designed to operate such that the paper making process is continuous. An empty spool is staged in the primary arms while the sheet is being reeled up. When the reel set approaches desired weight/set diameter, the primary arms lower, and the sheet is cut and begins turning up onto the new spool. Simultaneously, the reel set is moved away from the reel drum by the secondary arms, allowing the new spool to be lowered and set on the reel rails. Once the spool is lowered onto the rails, the primary arms disengage, the secondary arms move back into place to hold tension on the spool as it is building, and the primary arms are raised back into the upper position where a new empty spool can be loaded for the next reel set. Throughout this process, all components must work properly or a host of problems can arise.

Though some paper machines have newer, belted style reels, the majority of paper manufacturing facilities are operating with the basic designed reel, which consists of the following components:

- Drum

- Rails

- Primary Arms

- Secondary Arms

- Spools

Every inch of manufactured paper that is likely to be sold to perspective buyers, will be reeled. Paper machine reels must operate efficiently or the entire paper making process can stall. Good quality sheet can be dumped into the repulper, simply because the reel components failed due to misalignment. Misaligned components within the reel can cause sheet wrinkles, sheet breaks and improperly wound reel sets. All of these issues result in lost production and lost profit. Misalignment of reel components can also lead to hardware failure.

To ensure your reel is operating at design potential, it is important to perform alignment audits during routine maintenance outages. An alignment audit will determine:

- Alignment condition of the reel drum

- Alignment condition of reel primary arms throughout their length of travel

- Alignment condition of reel rails

Often, misalignment issues can be corrected during these outages.

Proper alignment of components will ensure efficient sheet transfer, reel turn-up and a properly wound sheet. By ensuring all reel components are properly aligned, your facility can benefit from improved production, increased machine speeds and higher profits.

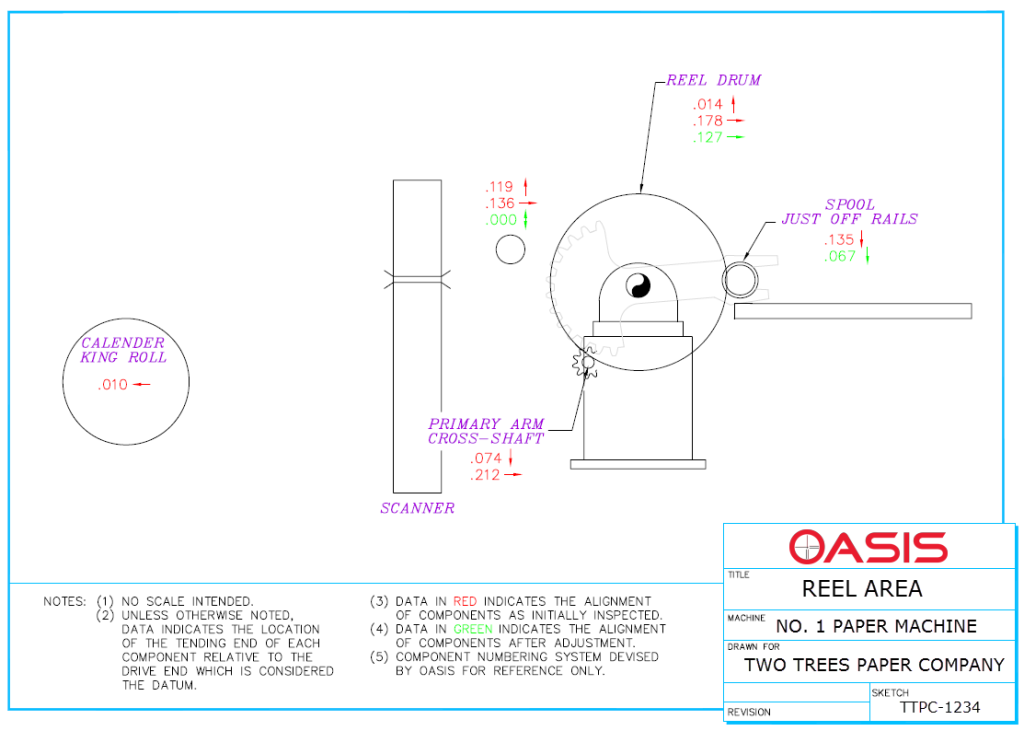

Drawing shows alignment data of reel components at initial inspection and after alignment adjustment

Be sure to check back for part two in our series on the precision alignment of paper machine reel components. If you would like to discuss your machine alignment needs or if you would like a site visit to your facility, please contact the OASIS Service Center nearest you.