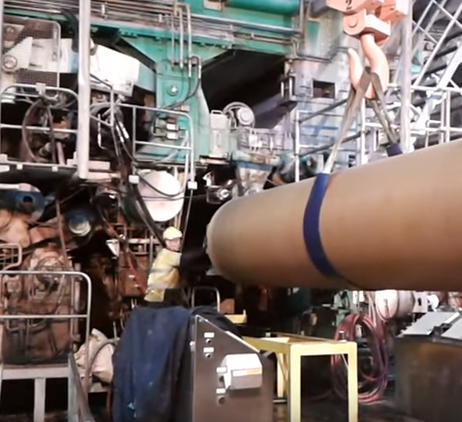

In order to operate your paper machines at the high speeds, longer operational periods, and higher operating efficiency required in today’s competitive environment, a planned roll maintenance policy should be adopted.

Paper machine rolls are the most numerous and often most complicated components of the machine. With performance standards higher, roll maintenance has become increasingly more important, especially in these areas:

- Rolls with working internals – these rolls must be capable of sustained and consistent high performance

- Roll surface condition – roll surface and crowns must be maintained for higher product quality

- Roll balance – in order to run at higher speeds, rolls must be balanced

- Roll alignment – planning roll alignment inspections in your maintenance program, will save you from the costly issues that can occur due to misalignment

Principles of Roll Maintenance

There are four approaches that you can take to your roll maintenance programs:

- Run to Failure. Also called “corrective” or “fix it when it breaks”. This approach will maximize run time between repairs, however – it can be very costly due to unplanned shutdowns and lost production. Additionally, if catastrophic failure occurs, many components can sustain damage. It is important to note that this approach is considered dangerous and is not recommended.

- Routine Preemptive. This approach includes doing all repair, replacement or overhaul on a set schedule. Component life is determined by theory and experience. The biggest problem associated with taking this approach, is that paper machines do not always follow the schedule and this can lead to needless repairs – or failures – ahead of schedule.

- Preventive Maintenance. Maximizing component life through alignment, roll grinding, balancing or lubrication is at the core of this approach. Though this will extend component life, it does NOT prevent failure.

- Predictive Maintenance. This approach is based on regular observation and measurement of the machine condition. Performed while the machine is down and while the machine is running, it includes temperature and lube oil checks, visual and audible checks and vibration analysis.

Combining Predictive Maintenance with Preventive Maintenance is the recommended best approach – doing both will help you to maximize up time, improve quality and prevent catastrophes.

Roll maintenance – either scheduled or unscheduled – is an essential aspect of your operation. Rolls must operate at the highest speeds and maintain the longest period of time possible between shut downs. Additionally, shut downs must be efficient and as short as possible. This can be achieved by planning a maintenance program that includes both predictive and preventive procedures.

In a future post on Maintenance Planning, we will provide an overview of the important steps to take as you create your roll maintenance program. Check back for new posts or Subscribe to Our Blog for regular updates!

Plan to Attend PaperCon 2016!

OASIS is honored to be presenting in two sessions at PaperCon 2016. This unique event for paper makers is produced by TAPPI and is being held at the Duke Energy Convention Center in Cincinnati, OH – May 15 -18, 2016. OASIS will also be exhibiting in booth #232. Be sure to visit us in the Exhibit Hall!

OASIS presentation details

“Detailed Project Planning Helps American Eagle Paper Mills Achieve Impressive Results” – Wednesday, May 18th at 8:00 AM in the “Papermaking: Who is Going to Do?” Track. Learn from Andrew Symons from American Eagle and Steve Pepin from OASIS, how adhering to a detailed project plan helped American Eagle Paper Mills achieve impressive results during a recent dryer can replacement project. Read Our Blog Post.

“Overlooking Rockers and Rocker Plates Can Lead to Dryer Component Failures” – Tuesday, May 17th at 1:30 PM in the OpEx Maintenance and Reliability Workshop. Learn from Myron Smith from OASIS, how neglecting the less visible components of your paper machine, such as rocker assemblies, can lead to serious and costly issues. Read Our Blog Post.

Contact Us for more information or for a FREE Exhibit Hall Pass!