In the nuclear sector, alignment tolerances are unforgiving, and timing is everything. OASIS Alignment Services combines precision machine alignment with 3D laser scanning to give nuclear operators the verified data they need to prevent costly delays. This article explores how pairing alignment expertise with advanced metrology reduces risk before the first outage task begins.

Planning for Precision: How Long-Range Laser Scanning Reduces Risk and Increases Uptime in Nuclear Facilities

In the nuclear power industry, operational runs often span 16 months or longer – evidence of the reliability and discipline that define this sector. But when it’s time for a planned outage, the urgency and complexity increase exponentially. Facilities must complete a wide range of inspections, upgrades, replacements, and regulatory tasks within a tightly controlled window – often just two to four weeks. There is no margin for error, and delays are not just costly; they can turn into compliance risks, safety issues, and grid reliability concerns.

That is why successful outage execution hinges on accurate, early-stage data—and why long-range laser scanning is quickly becoming essential to nuclear plant maintenance strategies.

High-Accuracy Data That Powers Planning

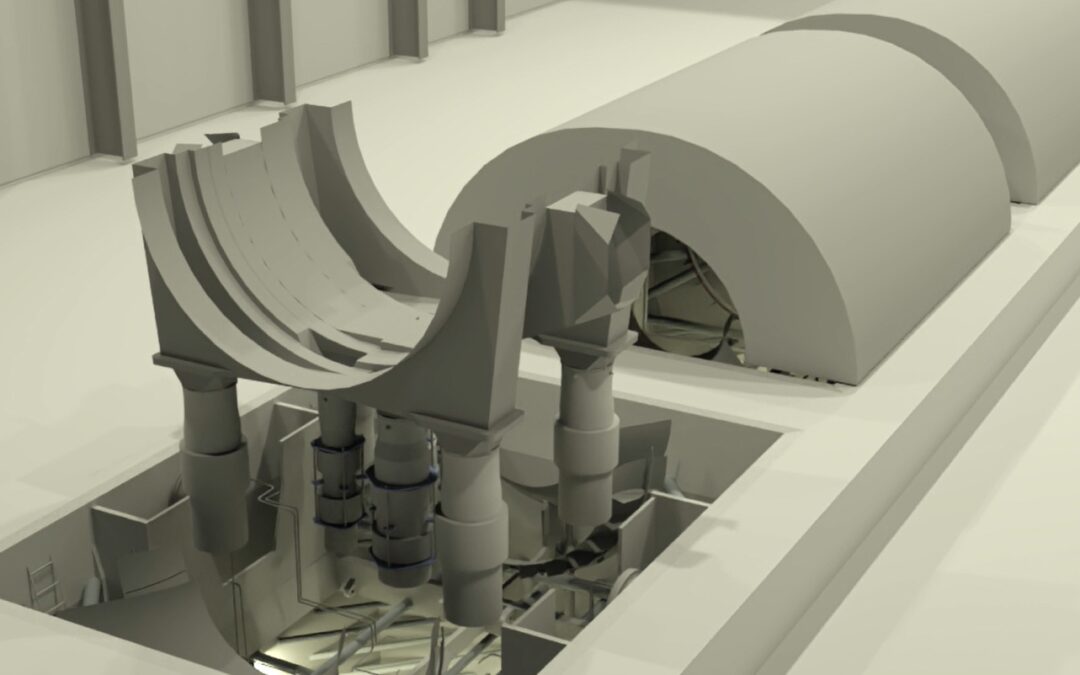

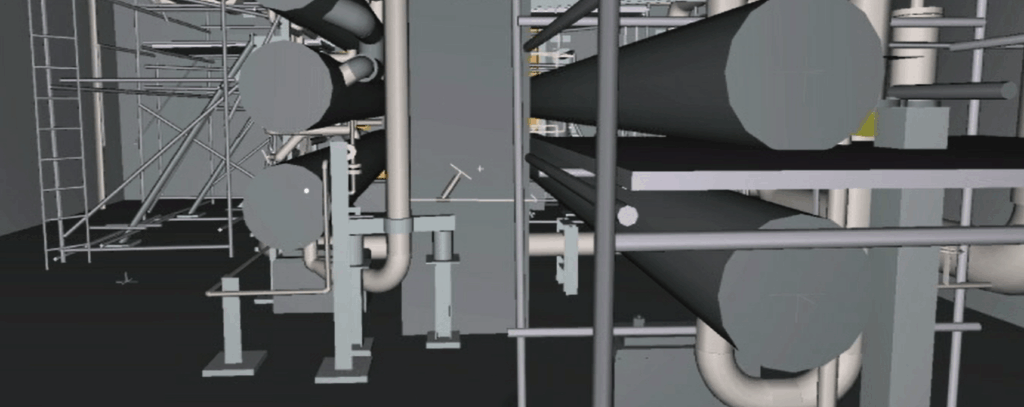

Long-range scanning captures a detailed, spatially accurate digital representation of the plant’s physical environment – everything from surrounding structures and embedded infrastructure to large components like heat exchangers, pumps, and piping systems. Conducted prior to the outage, this high-resolution 3D data allows plant teams and contractors to:

- Simulate and sequence work digitally

- Identify clearance conflicts and physical interferences

- Prefabricate parts with confidence and accuracy

- Design rigging paths and tooling strategies

- Validate fit-ups and tolerances long before field execution

In nuclear environments, where tasks are complex, spaces are constrained, and schedules are compressed, eliminating mid-outage surprises isn’t a bonus—it’s a requirement.

Virtual Fit-Ups: Reduce Risk Before It Starts

One of the most powerful applications of laser scan data is virtual fit-up—digitally verifying that replacement components, tooling, or assemblies will integrate seamlessly with existing conditions. This becomes mission-critical during operations such as reactor coolant pump (RCP) replacements, where clearances are minimal and tolerances are exact.

By capturing scan data during a previous outage, engineering teams can:

- Build high-fidelity CAD models of the plant environment

- Design custom components to real-world geometry

- Virtually test removal paths and installation procedures

- Pre-plan precision alignments and bolting patterns

This allows teams to shift from reactive to proactive, increasing certainty in planning and drastically reducing the likelihood of field adjustments that could delay restart.

Supporting ALARA and Compliance Goals

Long-range scanning also contributes to ALARA (As Low As Reasonably Achievable) objectives by reducing the number of personnel entries required for measuring, validating, or inspecting complex systems. Since data can be captured remotely and then shared digitally, planning teams, vendors, and contractors can coordinate off-site—limiting exposure during the outage itself.

The ability to pre-plan based on detailed, validated data also supports regulatory compliance by ensuring that upgrades and modifications proceed without deviation from engineered intent or licensing requirements.

Building a Living Archive for Long-Term Gains

Scan data isn’t just for a single project. When archived and integrated into the plant’s digital maintenance strategy, it becomes a valuable asset across the entire lifecycle of the facility. Over time, this growing database of as-built information allows teams to:

- Compare infrastructure conditions across outages

- Simulate future upgrades and change-outs

- Accelerate engineering reviews with accurate field data

- Reduce site visits and redundant measuring activities

Even if no active work is planned, capturing scans during the current outage ensures your team has the most up-to-date model for future use – empowering faster decision-making and higher confidence for what comes next.

Why Timing and Expertise Matter

Because outages are so infrequent – and critical – nuclear facilities only get one opportunity every 16+ months to capture this type of data. Miss it, and you’ll be planning the next outage with outdated or incomplete information.

That is why choosing a laser scanning partner with nuclear experience is non-negotiable. OASIS Alignment Services understands the stakes. We mobilize quickly, follow site protocols to the letter, and deliver actionable data that supports nuclear safety, precision, and schedule integrity.

Whether you’re planning an RCP replacement, a heat exchanger change-out, or simply building your digital maintenance archive, we are here to help make your next outage smarter, safer, and more efficient.

OASIS provides precision machine alignment and outage measurement services that help facilities meet ALARA objectives, reduce rework, and protect restart schedules. As part of the Measurement & Alignment Services Division of In-Place Machining Company, we partner with Exact Metrology and East Coast Metrology to deliver the industry’s most advanced measurement and alignment solutions.