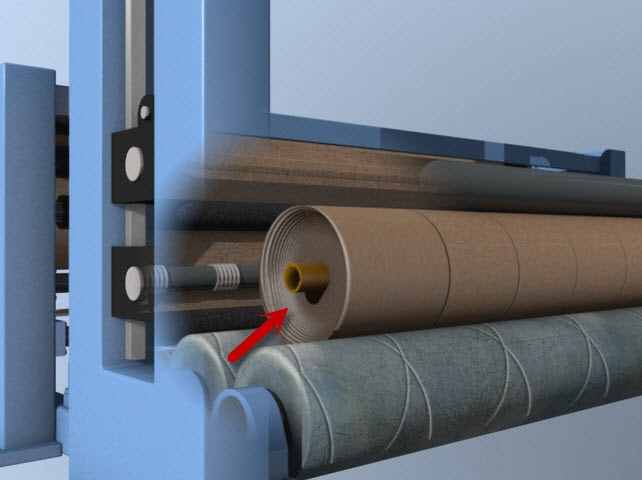

In our three previous posts on the Precision Alignment of Winders, we discussed the effects of winder misalignment on product quality and components as well as inspection and alignment techniques for the various areas of the machine – including the Unwind and Lead-in Rolls and the Slitter Section, Rider Roll Ways, Winder Drums, Rider Roll and Core Chucks. In this last post of the series, we provide tolerance guidelines and information relating to the importance of periodic alignment “tune-ups”.

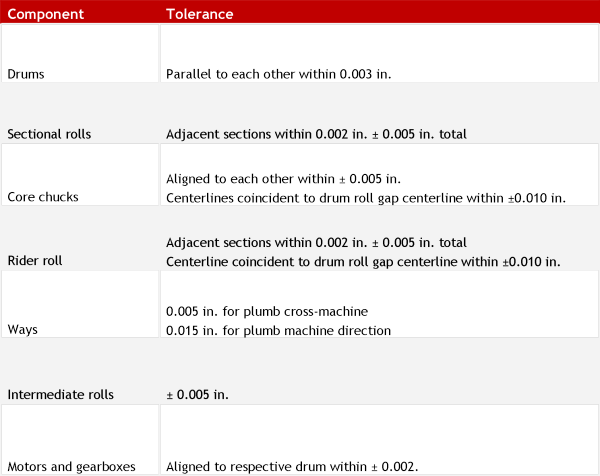

Tolerances

One must apply the OEM’s recommended tolerances when aligning winder components. If the manufacturer’s tolerances are not available or seem too large for the desired machine speed, follow the tolerances in the table provided below. Remember though, this table is only a guideline, since tolerances depend on equipment condition, operating speed, machine width and product type.

Periodic Maintenance

An aligned winder requires periodic inspections and adjustment to maintain the optimum operating conditions. “Tune-ups” should occur after approximately six to twelve months of operation. The replacement or repair of major components should be augmented with precision alignment techniques to maintain the winder’s alignment integrity.

Conclusion

Case studies have shown that precision alignment of winder components can typically result in large speed increases, significant waste reduction and fewer roll defects. Employing the methods discussed in our series on winder alignment (see earlier posts) and adopting an alignment maintenance program will help ensure that the winder operates to its fullest potential.

We hope you found the information in our Precision Alignment of Winders series to be of value. Please contact us with any questions or if you would like a site visit to discuss winder issues you may be having.