Fabric performance plays a critical role in sheet formation, water removal, and sheet drying. The precision alignment of components in the forming, pressing and drying sections can have a significant effect on fabric operation. Misalignment in these sections can cause issues such as trade seem skew, fabric weaving, fabric slipping on driven components, uneven nips, and more. In our two-part series, you will learn the importance of precision alignment as it relates to fabrics, sheet formation, and the water removal process. Additionally provided, are alignment tips and techniques for the forming, pressing, and drying sections as well as, an overview on how precision alignment can help to increase efficiency and machine performance.

What is Precision Machine Alignment?

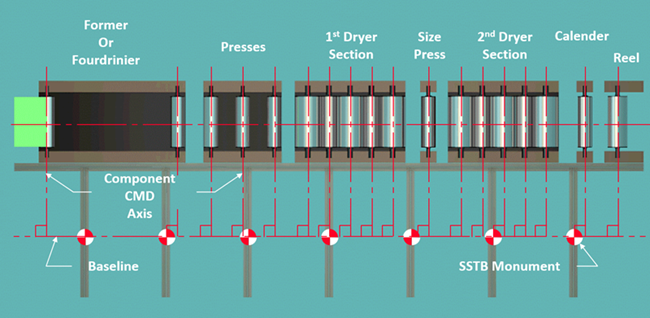

Precision refers to being exact or accurate and alignment refers to the arrangement of objects either in a straight line or in a correct or appropriate location/relative position. When we speak of ‘precision machine alignment’ we are typically referring to the level, square and/or parallelism condition of components within the machine; level to earth and square/perpendicular to machine centerline.

Alignment and Effects on Fabric Function

Each section will have specific issues with misalignment and respective fabric, but in general they are all the same. If a fabric is being skewed (trade seam skew) or wandering (moving in the cross-machine direction) or running off one side of machine and damaging the fabric, it is not performing as designed. Misalignment of rolls will cause these issues.

Sheet formation can be directly affected by fabric performance. The headbox distributes a uniform, fiber-slurry (stock) across the wire. If fabric trade seam is skewed, the weave is being closed and water will not flow through as designed. This will have negative effects on sheet formation as well as water removal. It is the same for press fabrics – skew tightens weave, not allowing optimal water removal from sheet nor drying of fabric across vacuum boxes.

Similarly in dryers – misalignment within felt runs can cause uneven tension of fabric on dryers resulting in uneven drying of sheet. There is also potential for wrinkles in both fabric and sheet.

Alignment Effects in the Forming Zone

In general, formers are designed to do just that – form a sheet and remove a significant portion of water from the sheet. Regardless of machine configuration – Fourdrinier design and/or some type of twin wire former – alignment is extremely important.

If table components are not properly aligned, the wire is not supported evenly or remove equal amounts of water across the width of the table.

Manufacturer design specifications including alignment of components and designed geometry, are required for optimal performance of any machine. Impingement angles and the position of forming board/blades and associated rolls, will have a direct effect on quality of product and formation of sheet. Also critical to sheet formation and water removal are the proper location of breast roll centerline to apron, gap between breast roll and apron, location of forming board (machine direction location and elevation), and having table components aligned to a plane established between the tops of the breast roll and couch roll. Additionally, if your machine has top formers, alignment in these areas is equally important. It would be a waste to form a quality sheet and then ruin it when you apply another layer or run through a top former to hopefully obtain the two-sided sheet desired.

It is just as important for all rolls within a wire section to be properly aligned. Misalignment can, and will, cause wire tracking problems as well as skew in wire trade seam. Even when all table or foil blades are properly aligned, water will not be removed as it should if the wire is skewed. It restricts the openings in the wire, thus restricting the flow of water.

Alignment Effects in the Press Section

The press section removes even more water from the sheet by passing the sheet between rolls and/or shoe press components that apply pressure and thereby transfer water from the sheet into the fabric/felt.

Press rolls should be aligned parallel within 0.005” over the length of the roll surface. Shoe press components should be aligned parallel and to manufacture specifications of shoe centerline location relative to roll centerline. Misalignment between press rolls/components will create an uneven nip due to more pressure being applied to one side versus the other. Uneven nip will not allow for even water removal across the width of the sheet and render the press inefficient. Furthermore, uneven nips can cause premature wear of press fabrics.

All rolls within a felt run should be aligned level and square to machine baseline or in a worst case scenario, all rolls within a felt run should be aligned in a similar level and square condition. This will allow the felt to track properly and keep the trade seam aligned. Trade seam skew in a felt is comparable to skew in a forming zone wire. Skew will not allow water to flow into and out of the felt as designed.

A properly aligned machine should have all rolls and components aligned level to earth and perpendicular square) to the baseline.

In Part Two of this series, we provide Alignment Effects in the Dryer Section, Alignment Tips & Techniques, an overview of Alignment Tooling & Technologies, and the Benefits of Precision Alignment. Be sure to check back soon for Part Two or Subscribe to our email list for this and more educational articles on precision measurement tooling and technologies, machine alignment methods, case studies and more.

If you would like to speak to an OASIS representative about issues you are having in your production line, we would be happy to help. Please Contact Us today!