With 2016 rapidly coming to a close, we thought we would take this opportunity to provide our readers – both our regular visitors and our new – with our top five most viewed blog posts. OASIS strongly believes that an informed, knowledgeable customer achieves the greatest success – which is why we strive to generate educational posts on all things related to industrial precision measurement and machine alignment.

We appreciate our readers! If there are topics you would like to learn more about or have questions on any of the material provided in our blog, please contact us. For additional industry knowledge, be sure to also make use of our Resources page where you can download presentations, case studies, the Machine Alignment Handbook, and more.

Repeatability in Measurement – Why is it Important?

When speaking of measurements, accuracy is the topic that is most often discussed. But in fact, there is something equally important that is often overlooked – repeatability, otherwise known as precision. When measuring in industrial conditions, a service company can take alignment measurements with less than perfect instruments and achieve a specification of accuracy. Yet, unless the measurements can be repeated, you are actually not precise at all. There are many factors that come into play that affect the ability to repeat measurements including poor instrument quality, instruments out of calibration, inadequate methods of data collection and operator inefficiency or inexperience. . . READ THIS POST

Why Laser Trackers for 3D Precision Measurement?

Everyone seems to be talking about laser trackers in the precision measurement industry – and there are many good reasons why. Laser trackers are extremely appealing metrology instruments for numerous reasons including size, portability, repeatability and accuracy. Add to that the ability to capture large volumes of 3-dimensional coordinate data quickly and in real-time, well it is no wonder they are so popular. We here at OASIS are certainly big fans and have added sixteen laser trackers to our arsenal of precision measurement tooling. Laser trackers measure 3-dimensional coordinates with impressive, and highly repeatable, accuracy in their operating volume. . .READ FULL POST

The Versatility of Modern Metrology Devices

It is often a preconceived notion that precision is the defining strength of a measurement device. While it is true that many applications require extreme precision and accuracy, other applications can simply benefit from the versatility of such devices. Laser trackers are portable coordinate measurement devices where in most applications their precision is called upon for the demanding tasks of dimensional control of highly accurate tool or parts inspections, but the portability and versatility of laser trackers, is what also makes them especially useful in areas that may not require tight tolerances. . . READ THIS POST

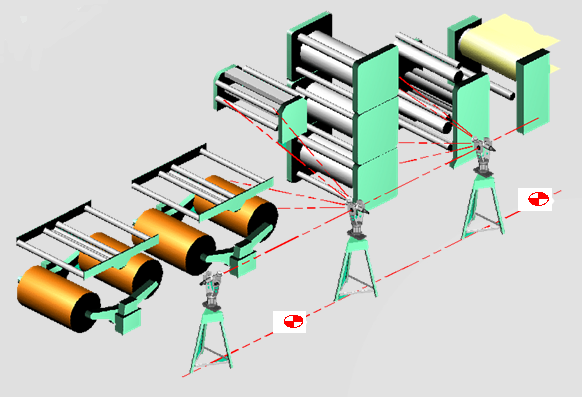

How to Align Machines – Getting Back to Basics

With many options in alignment tools and solutions available to manufacturers today, it is important to understand some basic principles of machine alignment so that you are making an informed decision when selecting the best solution for your particular machine or production line. Many of the costly equipment and product issues that manufacturers face on a day to day basis can be attributed to the misalignment of components within the process line. When components such as rolls, rails, dies, gears, motors, jigs, cutters, drums and more, are not properly aligned and working in unison with the other components of the line, manufacturers will see a significant increase in waste and scrap, poor product quality, a rise in unplanned downtime, and . . .READ THIS POST

Understanding Vibration, Balancing and Alignment

In the intensive, demanding and hectic world of industrial maintenance, it can be hard to understand the differences between vibration, balancing and alignment. In this post, we provide an overview of each and why they are critical to maintaining the health of your equipment. . .READ THIS POST

Thank you again for visiting our Industry Blog – we wish everyone a happy and safe 2017!