Written by Hubert Meagher, OASIS Director of Metrology Services, this post recently appeared on the Talking Points Blog published by Hexagon Manufacturing Intelligence. In future posts, we will provide additional technical information on the capabilities of our AT960 laser trackers and also delve deeper into the benefits to our customers of our using this innovative laser tracker for gathering highly accurate dimensional measurements at their location.

With thousands of successful projects completed since 1982, OASIS Alignment Services is the largest and most experienced service provider in the business of industrial precision alignment, machine maintenance, and machine installation. Customers, whether they are in the pulp and paper, plastics and film, converting, aerospace, automotive or power generation industry, all rely on one very important service from OASIS – highly accurate, reliable, precision measurement.

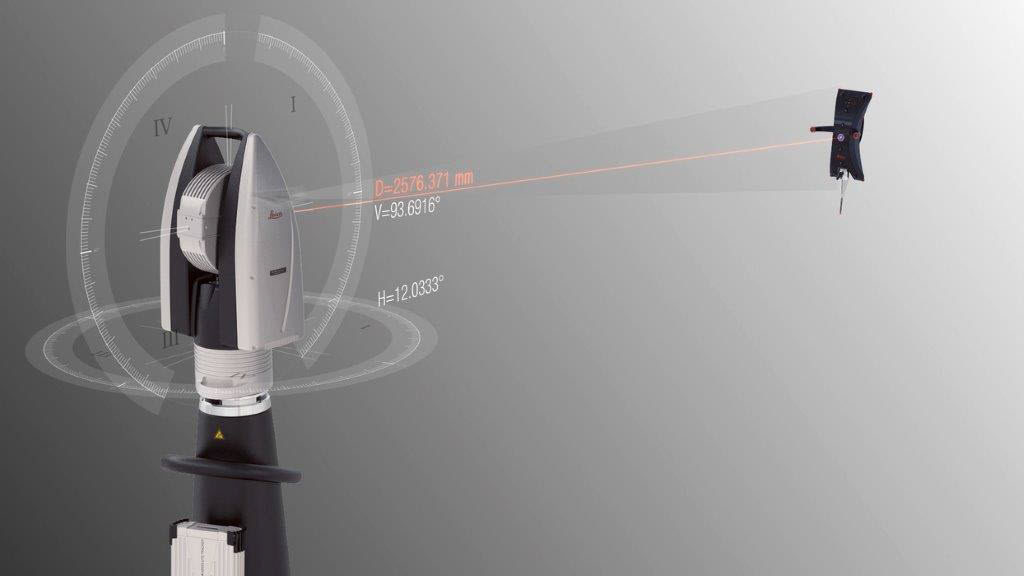

It is critical to customer success, that the instruments used by OASIS engineers and field service technicians are of the highest caliber and standardized across the fleet. After a full year of rigorous field testing of the Leica Absolute Tracker AT960 laser tracker, OASIS has entered into a technology partnership with Hexagon Manufacturing Intelligence and retooled its entire 3D metrology operation, moving from fifteen traditional laser trackers to thirteen AT960 laser trackers paired with Leica T-Probes.

T-Probe allows for inspection of hidden or hard to reach places

OASIS performs measurement tasks in many industries and for a wide variety of processes. In the roll alignment process, one of the hurdles of using a laser tracker in the past has been restricted line of sight. In order to properly model a cylinder in 3D space, sufficient circumferential coverage needs to be measured. When line of sight is restricted, it is difficult to obtain enough data at either end of a roll in a single device position. The 6DoF Leica T-Probe, with its variety of probes and styli, provides the flexibility to cover more of the roll and measure without direct line of sight to the roll face, thus solidifying confidence in the field measurements. The ability for the Leica T-Probe to measure dynamically as well as static points makes it a very powerful tool in our new cutting edge toolbox.

Device position planning can be challenging in the field. Prior to using the AT960 laser tracker, there were many times when even the most careful positioning of drift nests in restrictive areas would fail when the device was relocated. When uptime is crucial to the customer, having to reset additional drift nests due to this type of failure is unacceptable – and needless to say, extremely frustrating for the OASIS metrology engineer. With the Leica T-Probe extensions and styli, even inaccessible drift nests can be measured easily and accurately.

One of the key services provided by OASIS is layout work. In order to perform this previously, a special nest was needed in order to track the SMR to the desired location. The SMR would then be removed and a transfer punch was inserted to mark a set point. If the surface was magnetic, this could be accomplished with a fair amount of reliability, but on other surfaces the repeatability of the operation was questionable. By placing a scriber point on the Leica T-Probe, locating and marking set points is now much easier and more efficient. u

The capabilities of the 6DoF Leica T-Probe are just one of the many innovations of the AT960 laser tracker that closed the deal for OASIS. Forming this technology partnership, allows OASIS to better serve their customers and help Hexagon Manufacturing Intelligence develop innovative technology for the markets that OASIS serves.

For more information on how your facility can benefit from the metrology services provided by OASIS, please contact the OASIS Service Center nearest you. Be sure to subscribe to our blog for regular updates on precision measurement technologies, industry news, case studies and more.