With close to 35 years in the field of industrial precision measurement and alignment, the engineering team at OASIS has worked with, tested, researched, and owned almost every precision measurement instrument available – from machinist levels, pi tapes and trammels to optical alignment tooling and 3D metrology instruments such as laser trackers and portable measuring arms. In our Measurement Tool Spotlight series of posts, we will select a precision measurement tool and provide an overview of the tool and the applications it is best suited for.

Portable Measuring Arms

Originally designed to inspect the geometric path of bent tube shapes, portable measuring arms, also known as articulating arms or 3D metrology arms, have been in existence for many years. With today’s technology and software, these innovative measuring instruments are used for dimensional analysis and quality control in a wide variety of industries including aerospace, automotive, power generation, tool & die manufacturing and metal fabrication.

How the “Arm” Works

Portable measuring arms are portable coordinate measuring machines that resemble a human arm with an elbow, forearm and wrist. A probe is located at the very tip of the arm and high precision angular encoders are located in each joint. The encoders precisely calculate the 3D coordinates of the probe as it is positioned on the component or part that is being measured.

Portable measuring arms are available in a number of different models with measuring reach from 4’ to 14’ and with either six or seven axes of rotation. This flexibility allows for precision measuring even in difficult to reach areas.

Accurate to +/- .001” and with internal temperature sensors, portable measuring arms easily compensate for the effects of environmental temperature changes.

Additionally, all portable measuring arms communicate with 3D metrology software, allowing for inspection reports to be generated quickly – often provided onsite and in real-time.

Applications Where Measuring Arms Excel

With their high degree of accuracy, flexibility and portability, measuring arms are ideal for numerous industrial applications including:

- Dimensional Analysis

- First Article Inspection

- CAD-Based Inspection

- On-Machine Inspection

- Reverse Engineering

- Tool & Fixture Alignment

Laser Line Scanners

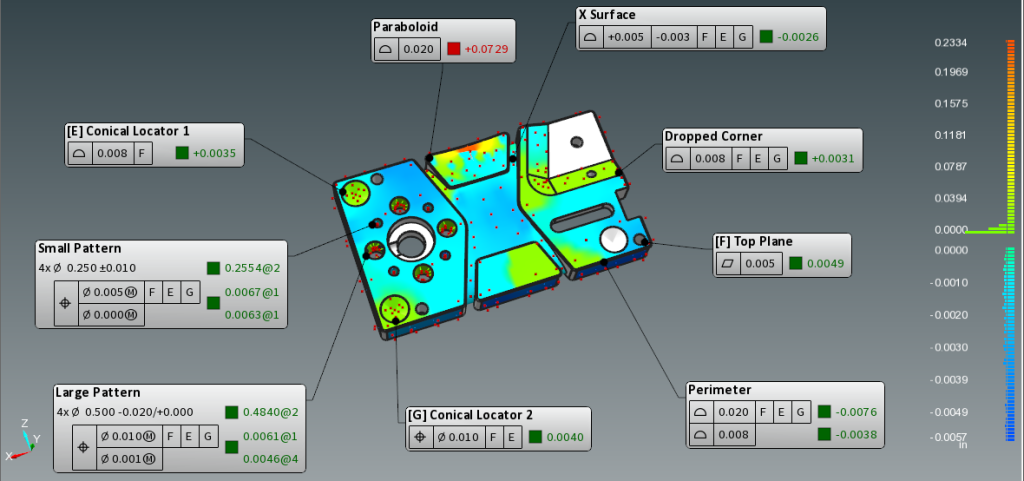

Some portable measuring arms can be modified by attaching a laser line scanner/probe. Laser scanners capture non-contact measurement data quickly and at a high frequency – often over 20,000 points per second. The advantages of non-contact scanning include improved surface scanning, ease of use on complex parts, and speed of data collection. Applications that benefit from portable measuring arms with laser line scanners include reverse engineering, CAD-based inspection and first article inspections.

Image shows dimensional model of part created using portable measuring arm and BuildIT 2016 software

Summary

Traditional coordinate measuring machines (CMMs) are ideal for the dimensional inspection of large numbers of the same parts. However, traditional CMMs are typically in a fixed location, extremely costly, and have limited measurement reach. With the portability, reliability and efficiency of portable measuring arms and other portable metrology instruments, such as laser trackers, metrology engineers have the ability to inspect parts and components directly on the shop floor. This capability allows for quick diagnosis of issues, fewer part defects and improved quality of both product and process.

Note: Contract work for a limited number of parts, whether done at your facility or at a metrology vendor’s location such as at an OASIS Service Center, is a good alternative to purchasing an arm and 3D metrology software – and eliminates the expense of training an in-house resource. If you would like more information on portable measuring arms or other 3D metrology tools and solutions, please contact us – we would be happy to discuss your needs.