The workhorses of the machine alignment field, optical alignment instruments have been used for precision measurement in industrial settings for many years. Rugged and dependable – and highly accurate to one arc second (0.001″ over 17 feet) – optical alignment tooling continues to be the tool of choice for many applications where the measuring environment is less than ideal. Paper mills, steel mills, converting and corrugating facilities, power generating plants, and more, benefit from the accuracy and reliability of optical tooling and alignment methods. In this post we provide you with definitions for terminology that you may hear during a machine alignment inspection or alignment procedure where optical alignment instruments are being used.

| Optical Instruments | ||

|---|---|---|

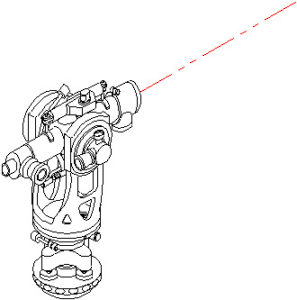

| Alignment (Control) Instrument |  | An optical instrument used to establish a reference Line of Sight (LOS) from which other optical instruments can be collimated or collineated. Usually this control instrument is bucked-in to the machine baseline. |

| Sight Level |  | An optical instrument used for measuring the level to earth condition of machine components. |

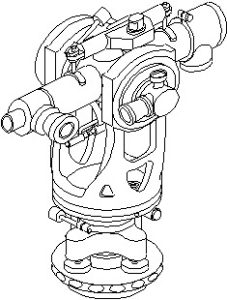

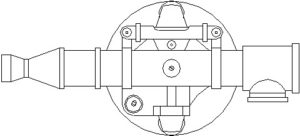

| Telescopic Transit Square (TTS) |  | An optical instrument which consists of two optical systems arranged exactly 90 degrees to each other. These systems form accurate perpendicular Lines of Sight (LOS). |

| References | ||

|---|---|---|

| Baseline |  | A parallel reference line which represents the machine centerline. It is usually established by Stainless Steel Target Bushings (SSTBs) or brass plugs embedded in the floor on the operator side of the machine. In the case of newer free standing equipment, this reference is installed in the cross-machine direction directly in the frame or sole plates. |

| Brass Plug |  | A monument embedded in the floor with an affixed prick punch mark used as a reference point on a baseline |

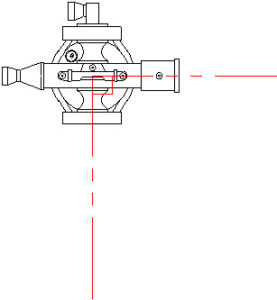

| Line of Sight |  | A line projected by an optical instrument from which all measurements are made. |

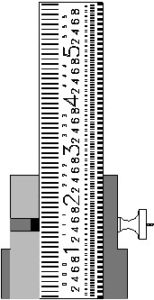

| Optical Scale |  | A device that has accurately positioned increments which can be measured optically. |

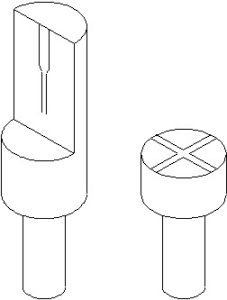

| Optical Target |  | A device inserted into a Stainless Steel Target Bushing (SSTB), with accurately positioned patterns which can be measured using optical tooling. |

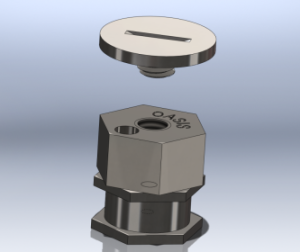

| Stainless Steel Target Bushing (SSTB) |  | A machined busing designed and used exclusively by OASIS in the installation of baselines. It performs the same function as a brass plug, but is far more accurate due to its ability to accept and optical target |

| Stick on Target |  | An adhesive backed optical target used as a temporary reference where permanently fixed target bushings are not always practical. |

| Procedures | ||

|---|---|---|

| Buck-In |  | Setting a Line of Sight (LOS) parallel to at least two reference points such as Stainless Steel Target Bushings (SSTBs), brass plugs (BPs), or both ends of a machine component. |

| Collimation |  | Setting two optical instruments so that their Lines of Sight (LOS) are parallel but not coincident. |

| Collineation |  | Setting two optical instruments so that their Lines of Sight (LOS) are coincident. |

| Planizing |  | Setting an instrument's Line of Sight (LOS) parallel to a given plane. This plane can be defined by three points, or by two points and a level instrument. |

For an in-depth description of the Telescopic Transit Square (TTS), check out this article Measurement Tool Spotlight: The Telescopic Transit Square (TTS). If you would like to learn how precision machine alignment can increase efficiency at your location, please contact us and be sure to subscribe to our email list for regular updates on precision measurement tools and technologies, alignment methodologies, case studies and more.

Consider the following Information :

Two set two optical instruments so that the LOS are coincident ( collineation )

a infinity target and a target on the center of the objective lens is required.

Like a K&E 71-2022 alignment telescope or a K&E 71-4010 collimator or a

K&E 71-2062 line of sight telescope.

Your example does not have targets on the objective lens of either instrument.

Call me if you do not understand this.

For Best Calibration of optical instruments it is required that the collimators

and instrument being calibrated LOS are almost set to be in coincident.

Bill,

I understand your comments, but we can perform collineation in the field (rarely performed but proven) with two Brunson Model 76RH TTS containing a right angle eye piece with adaptor on back of eyepiece that accepts a light for illuminating the reticles.

1. The first instrument must be precision leveled and have an established line of sight (LOS); bucked-in to the machine baseline. The second instrument must be mounted on a cross slide, precision leveled and collimated to first LOS (main barrel to main barrel).

2. The first instrument is then focused to an exact point in space (approximately 1/2 distance between instruments. A white sheet of paper will work; held by a technician so focus to that point can be achieved).

3. The second instrument is then focused onto the illuminated reticles of the first instrument.

4. If necessary, adjust instrument two, by means of cross slide, until the vertical wire images of both telescopes are in register.

5. Now, both instruments must be focused to infinity.

6. If the reticle images now appear to be out of register, use the horizontal tangent screw of instrument two, only to bring the verticle wire images into register.

Repeat steps 2-6 until no adjustment is required at steps 2 & 6. Of course, each adjustment of instrument two will require precison level of instrument after each adjustment.

I hope this helps.

Best Regards,

Myron Smith