OASIS Alignment Services Standardizes Entire Metrology Fleet with Hexagon Manufacturing Intelligence 6DoF Solutions

Leading service provider replaces traditional 3D laser trackers with next-gen Leica T-Probe Field Solutions

Hexagon Manufacturing Intelligence announced today OASIS Alignment Services, LLC (Rochester, NH) has standardized its large metrology fleet on Leica Absolute AT960 laser trackers and Leica T-Probes. OASIS is a leading provider of 3D metrology, optical alignment, and mechanical services with eight regional service centers throughout North America. The company serves a broad spectrum of industries: pulp and paper, plastics and film, coating and laminating, nonwovens and textiles, power generation, aerospace, automotive and more. After one year of field testing two Leica AT960s in every customer case scenario, the company experienced 100% uptime with the portable measurement technology. OASIS has now retooled its entire field enterprise, moving from traditional laser trackers to the next-generation 6DOF technology of the Leica AT960 paired with the Leica T-Probe.

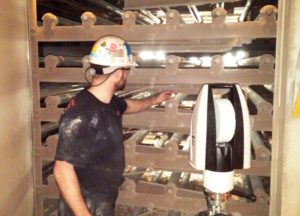

OASIS metrology engineer uses new Leica AT960 laser tracker to inspect wallboard process line.

OASIS engineers and field service technicians are proficient users of precision optical tooling and 3D measurement technologies including laser trackers and laser scanners. Uptime of portable metrology equipment is vital to efficiently solving problems in the field and minimizing costly customer downtime. OASIS no longer requires back-up spares in their metrology fleet based on the dependability of the Leica AT960 trackers. The Leica 6DOF technology has also provided increased accuracy for large-volume measurement tasks with much faster setup times. The wireless, handheld Leica T-Probe can access hard-to-reach points and gather data at a high point acquisition rate without multiple setups. A landmark advancement in the laser tracker field, Leica PowerLock technology automatically locks onto any moving target without user intervention. OASIS operators can move freely and focus solely on measuring, even in crowded job sites, without the worry of reestablishing a line-of-sight with the laser beam. The overall improved speed of measurement and “one person” operation of the Leica T-Probe 6DOF solution has positively impacted OASIS field completion rates.

“Reliable, failure free equipment performance is critical to our customers’ success, as well as our own success in providing solutions to our customers. It also provides peace of mind, as our field service technicians constantly face challenging jobs in formidable environments,” states Brian Hiltunen, OASIS President. “Our partnership with Hexagon Manufacturing Intelligence has given us access to the latest laser tracker technology with high precision measurement capabilities and superior dependability in the field. This transition has enabled us to maintain 100% uptime with 13% fewer trackers in our fleet. OASIS service personnel can sleep at night knowing their metrology tools will work the next morning, so they can accomplish each job with confidence.”

“Hexagon Manufacturing Intelligence is very pleased to partner and support OASIS Alignment Services, a top performing service organization in the industrial sector. Their seasoned experts have an in-depth knowledge of industrial metrology applications and how alignment issues impact processes and overall machine efficiency. When you are in the field solving a customer crisis, time is of the essence and your problem-solving tools must be rock solid. OASIS is already seeing ROI and related savings as the 6DOF technology is reliable day in and day out,” concludes Joel Martin, Product Manager,Trackers, Hexagon Manufacturing Intelligence.

About OASIS Alignment Services

With thousands of successful projects completed since 1982, OASIS is the largest and most experienced service provider in the business of industrial precision alignment, machine maintenance, and machine installation. By aligning customer needs with their capabilities, OASIS becomes an integral part of improving manufacturing efficiency and reducing costly customer issues. OASIS engineers and field service technicians respond quickly and efficiently from eight regional service centers strategically located across North America. For more information, visit oasisalignment.com.

About Hexagon Manufacturing Intelligence

Hexagon Manufacturing Intelligence helps industrial manufacturers develop the disruptive technologies of today and the life-changing products of tomorrow. As a leading metrology and manufacturing solution specialist, our expertise in sensing, thinking and acting – the collection, analysis and active use of measurement data – gives our customers the confidence to increase production speed and accelerate productivity while enhancing product quality.

Through a network of local service centers, production facilities and commercial operations across five continents, we are shaping smart change in manufacturing to build a world where quality drives productivity. For more information, visit HexagonMI.com.

Hexagon Manufacturing Intelligence is part of Hexagon (Nasdaq Stockholm: HEXA B; hexagon.com), a leading global provider of information technologies that drive quality and productivity across geospatial and industrial enterprise applications.

For more information regarding the OASIS technology partnership with Hexagon Manufacturing Intelligence, please read official Hexagon MI release or contact Hubert Meagher, Director of Metrology Services, OASIS Alignment Services, LLC.

Gentlemen: Being myself engaged in the field of industrial technical training and maintenance, As a passionate follower of metrology issues, I admire and value high the esforth that OASIS is doing to maintain up-to-day its applied technology in industrial machinery and equipment alignment. In other sense, I´d considered laser alignment as a non plus ultra technology; so I´ve been “shocked” for the new HEXAGON technology you are using nowadays. Many thanks for publising your experiency in that area.

Pedro A. Henríquez ..