The workhorse of optical alignment tools, the telescopic transit square (TTS) continues to be a top choice for alignment inspections in extreme environments such as paper mills, steel mills, power plants, and other manufacturing facilities where the environment is less than ideal. In this post we provide you with a brief overview of how transits work and the benefits of using them in industrial applications.

What is a Telescopic Transit Square?

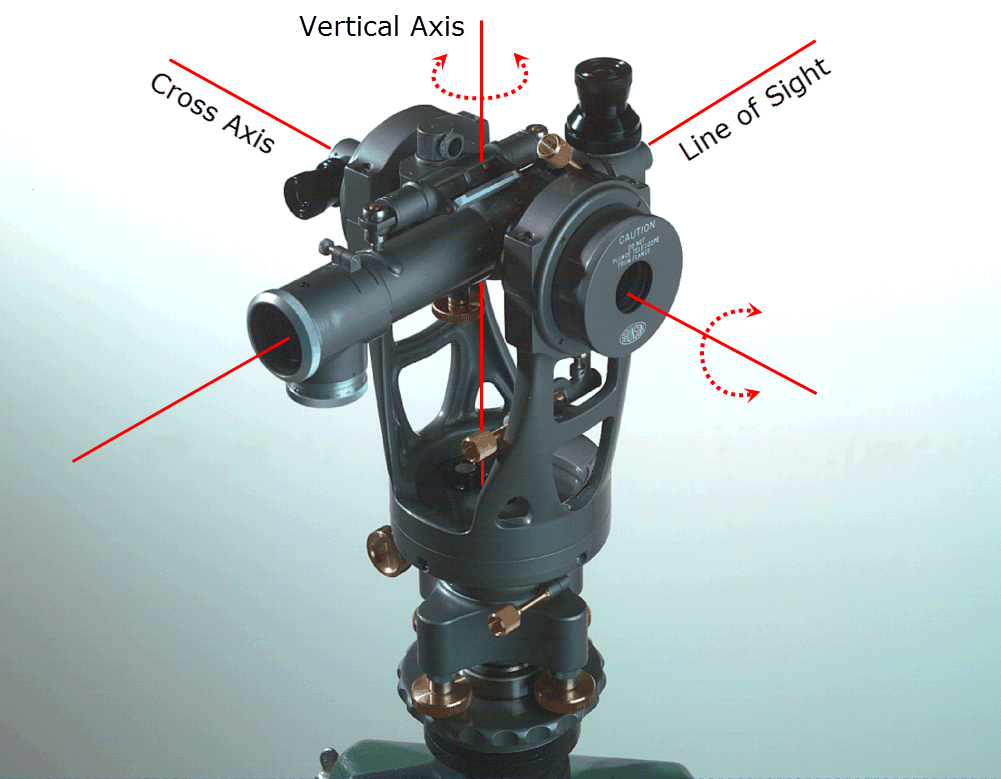

Telescopic Transit Squares (TTS) are highly accurate precision measurement instruments that use planes or Lines of Sight (LOS) formed at 90-degree angles in both horizontal and vertical directions. The TTS is equipped with a telescope on a gimballing mechanism allowing it to rotate back and forth horizontally (azimuth direction) and rotate up and down (elevation direction).

Most people are familiar with or have seen a surveyor’s transit. Though the TTS looks similar to a surveyor’s transit, there are some significant differences. With a number of modifications, optical tooling transits are highly accurate over distances that would seem short to a surveyor (such as less than a 200’). Additionally, optical tooling does not require readings in two telescope positions (direct and reverse) in order to achieve this accuracy.

The Telescopic Transit Square has three orthogonal axes that intersect at exactly the same point in space – which is extremely important when high accuracy is essential

OASIS currently has twenty eight optical tools sets, all containing the 76RH TTS from Brunson, a longtime leader in the development of precision measurement instruments. Special characteristics associated with this TTS include:

- They have an extremely straight Line of Sight (LOS). When focusing the telescope from near to far, the LOS travels in an extremely straight line.

- Transits have three major orthogonal axes (all at right angles to each other).Two axes are rotational – the vertical axis and the cross-axis. The third axis does not rotate, this is the LOS.

- All three axes meet at one precise point. That is, all lines intersect at the same exact point in space. This is especially important when accuracy is essential, particularly at shorter distances.

- A big distinction of the 76RH transit is that it has an optical cross-axis – an infinity-focused telescope housed in the cross-axis. This cross-axis telescope can be used to set the main scope perpendicular to another scope or mirror – when mounted on a rotating shaft or other reference plane, for example.

What is a Telescopic Transit Square Used for?

Accurate to 0.001” over 17 feet under ideal conditions, the TTS is a very flexible tool. Using a TTS, optical alignment engineers can establish extremely flat vertical or horizontal planes as well as establish straight optical lines extending in many directions. Once planes and lines are determined, they can be used as references from which other points can be measured.

With a Telescopic Transit Square an engineer can determine whether machine components are parallel, flat, level, square or straight – allowing evaluation of geometric relationships related to alignment of parts, structural components, machines, tools and more.

OASIS optical engineers use transits to determine a machine centerline in order to install an offset baseline which becomes a permanent reference. Once this has been done, optical engineers can:

- Measure the machine as it currently exists

- Provide an alignment profile

- Provide a basis for maintenance planning and operational troubleshooting

- Establish a permanent alignment reference for all future machine alignments, machine rebuilds and installations

- Provide references from which we can monitor machine movement caused by building or machine settlement or thermal cycles

For more information on optical alignment tooling and methodologies or for a site visit to your facility, please contact the OASIS Regional Service Center nearest you. And, be sure to check back for future “Measurement Tool Spotlight” posts to learn more about how precision measurement instruments work and the benefits they provide.