In industry, the requirements for alignment are numerous. From shaft alignment to satellite antenna alignment to roll alignment, engineers and technicians benefit from a wide range of technologies and methods to accomplish their measurement and alignment needs. In “How to Align Machines – Shaft Alignment” we provide you with alignment basics for shaft and coupling alignment along with an overview of shaft alignment methods and tooling. Additionally, we have included the following links to other informative articles that may be of benefit to you and the team at your facility:

Shaft Alignment

One very common application in industry is coupling or shaft alignment. Click here to read about How to Align Machines – Shaft Alignment

Getting Back to Machine Alignment Basics

With many options in alignment tools and solutions available to manufacturers today, it is important to understand some basic principles of machine alignment so that you are making an informed decision when selecting the best solution for your particular machine or production line. Click here to read about How to Align Machines – Getting Back to Basics.

How Often Do You Need a Machine Alignment Inspection?

Unfortunately, there isn’t a simple answer. There are a number of factors that can affect your equipment alignment, and these should be taken into consideration when creating a machine alignment inspection plan at your facility. In this post, we provide the top three factors that can determine how often alignment inspections are needed and discuss the reasons why there are no set rules that can be applied. Click here to learn How Often You Need a Machine Alignment Inspection.

Precision Drive Train Alignment

Alignment is critical to all types of drives, whether they be driven by belts, chains, gears, or shafts. Performing precision alignment of drive equipment helps eliminate catastrophic failures which can create unscheduled downtime, loss of valuable production time, extra in-house or contractor man-hours, and component costs. Click here to learn why Precision Drive Train Alignment is Critical to Rotating Equipment Efficiency.

Paper Machine Alignment Questions

We’ve put together a comprehensive collection of articles about paper machine alignment. Click here to have Your Paper Machine Alignment Questions Answered.

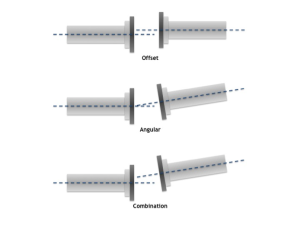

Types of shaft alignment.

One very common application in industry is coupling or shaft alignment. For maintenance and economical purposes, it would be very impractical for a pump and motor to be constructed using a common shaft. Motors (or the driving side of a propulsion system) are usually self-contained and easily replaceable. However, that leaves a joint in the drivetrain. If the alignment between the components was perfect to begin with and remained perfect during the life of the components, then there would be no issue. However, when misalignment exists, a rigid coupling is extremely susceptible to fatigue failure due to the high number of cycles of bending imparted on the shafts. For this reason, flexible couplings are normally used between machine components. Couplings are mechanical devices with moving parts that are activated with every cycle. Depending on the type of coupling (usually determined by the speed and loading requirements), tolerances can vary dramatically. Some couplings are more forgiving in the radial direction while others can take more angular misalignment. Generally speaking, the greater the misalignment, the greater the movements of the parts within the coupling will be and hence the greater the wear will be.

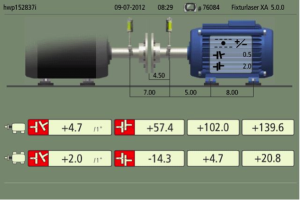

Coupling alignment results using Fixturlaser XA laser shaft alignment system.

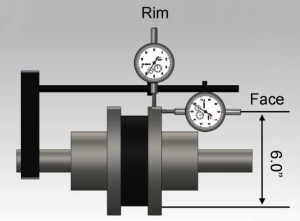

So it stands to reason that the better the alignment, the longer the coupling life. Although couplings exist to reduce the need for perfect alignment, for the most part it is critical for the driver and the driven within machine drives to be aligned to ensure coupling life. Coupling alignment can be achieved in many ways using several different techniques, including mechanical, optical, and laser. Mechanical methods, using dial indicators, parallel bars, and feeler gauges are battle tested and proven.

Coupling alignment by mechanical methods.

However, they rely 100% on human interpretation of the data and can be time-consuming. Optical methods are often used when components are separated by guards and/or large distances, or large offsets are involved (as with universal joint type shafts). Optical methods require a certain expertise and depend 100% on humans to interpret the data and calculate the alignments. Today, laser shaft alignment systems are most often used to align different types of industrial shaft and drive systems. Operators only need to enter geometric parameters and typically partially rotate the components to allow the computer to calculate the alignment and corrective parameters.