We know that our customers and prospects are very busy people. To help you quickly find informative articles that apply specifically to the needs of your industry, on occasion we will compile them in one post for fast access. In this post, we provide you with the links to all of our previously published articles on paper machine alignment. Whether you are new to the pulp and paper industry or have been running a paper machine for many years, these educational articles will be of benefit to you as you look to improve operational efficiency at your mill. If you have questions on any of the information provided or would like more on a particular topic, please do not hesitate to contact us!

The Importance of Precision Machine Alignment During Paper Machine Upgrades and Conversions

With the evolving market demands for paper – decreased use of printing and writing paper and increased demand for paperboard, containerboard and cartonboard, many paper makers are upgrading their older paper machines in order to produce more profitable paper grades. In our three-part series, you will learn why precision alignment is critical to the success of the conversion. Read Series

How to Align Machines – Getting Back to Basics

With many options in alignment tools and solutions available to manufacturers today, it is important to understand some basic principles of machine alignment so that you are making an informed decision when selecting the best solution for your particular machine or production line. Read Post

How Often Do You Need a Machine Alignment Inspection?

One of the questions OASIS customers most often ask is “How often do I need to have my machine inspected for alignment?” Unfortunately, there isn’t a simple answer. In this post, we provide the top three factors that can determine how often alignment inspections are needed and discuss the reasons why there are no set rules that can be applied. Read Post

Importance of Precision Alignment for Wet End Upgrades

Competition in the paper industry can be intense – and getting the most from your paper machine is crucial. To remain competitive, paper companies are often upgrading (modifying, rebuilding and/or adding components to) their older machines in order to boost production and improve quality. Read Post

Overlooking Rockers and Rocker Plates Can Lead to Dryer Component Failures

The many components in a paper machine – both big and small – when working together correctly, keep the paper making process running smoothly. Unfortunately, it is easy to neglect some of the less visible components that are of importance. A prime example are the rockers and rocker plates within many common dryer sections. Read Post

Paper Machine Reel Alignment Can Help You Avoid Real Issues

In this two-part series, we discuss the importance of alignment in the reel section of your paper machine and provide some of the issues caused by misalignment, as well as the benefits of precision alignment. In the second post, we provide more detailed information on how to align the various components that make up a reel section including the reel drum, reel rails, primary arms, secondary arms and spools. Read Series

Precision Alignment of Winders

In this four-part series, we discuss the effects of misalignment on product quality and winder components, inspection and alignment techniques, alignment of the slitter section, rider roll ways, winder drums, rider roll and core chucks, and conclude with tolerance guidelines and information relating to the importance of periodic alignment “tune-ups”. Read Series

Paper Machine Applications Where Laser Trackers Excel

For most areas of a paper machine, the use of optical tooling continues to be the best option for gathering alignment inspection data. However, the capabilities of some of the newer, innovative 3-dimensional measurement tools such as laser trackers excel in several areas of the paper machine. Read Post

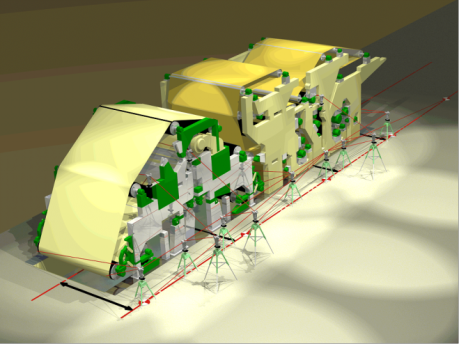

Fourdrinier Alignment Inspection is Now Much Faster and More Efficient

The Fourdrinier is one area of the paper machine where paper makers can benefit from the use of newer alignment technology such as the innovative AT960 laser tracker with T-Probe. Read Post

Reduce Costly Alignment Issues with Preventative Inspections

Paper mills can spend weeks and even months scheduling and planning their shutdowns, but can overlook day to day checking that could save time and money. Using a preventative maintenance strategy for alignment inspection of paper machine components is a highly suggested course of action. Read Post

Planning Paper Machine Roll Maintenance

In order to operate your paper machines at the high speeds, longer operational periods, and higher operating efficiency required in today’s competitive environment, a planned roll maintenance policy should be adopted. Read Post

Proper Bowed Roll Alignment Helps Reduce Uneven Web Tension

Bowed rolls can often be found in several areas of a paper machine and on most converting machines. The main function of bowed (or spreader) rolls in web production equipment is to spread the web and/or keep the web flat, as it runs through the processes. Read Post

For more information or to schedule a site visit to your mill, please contact us – an OASIS representative will be happy to assist you. Be sure to subscribe to our resources for regular updates on precision measurement tools and methodologies, case studies, technology reviews, and more.

Nice Post!