This article was originally published in 2015 – however, with the rise in demand for corrugated packaging, manufacturers of corrugated board can use all the help they can get to keep their corrugators running at peak performance. For an in-depth dive into corrugator alignment, be sure to download the replay of our webinar “How to Align Machines: Corrugators”.

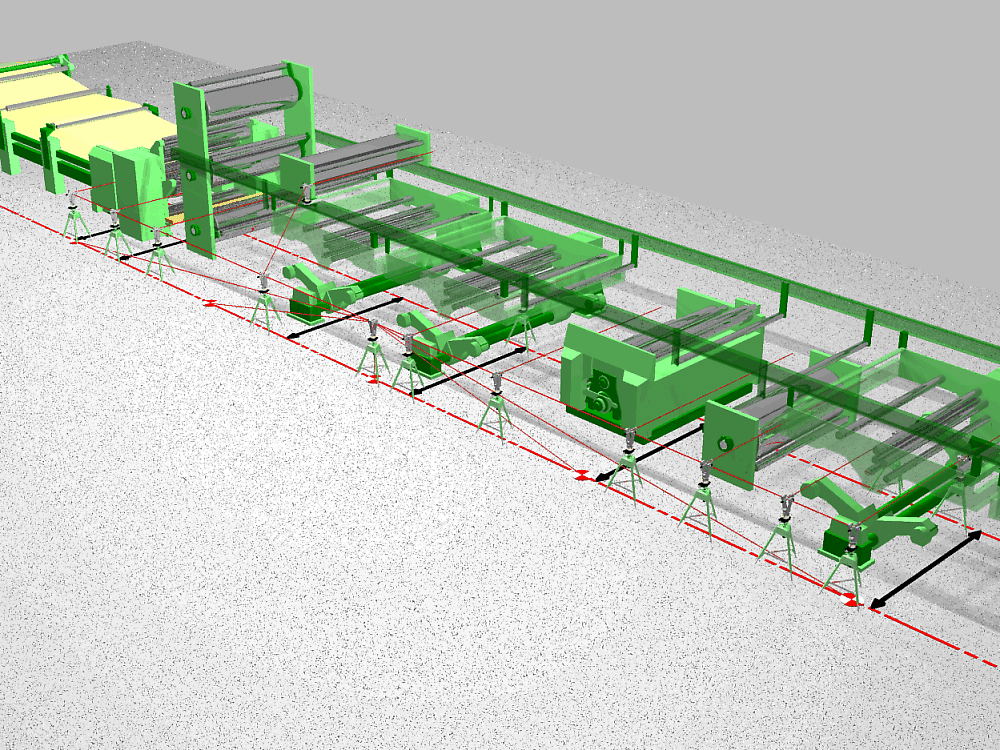

In a perfect world, all components within your corrugating line would be installed on centerline, perpendicular (square) to the centerline, and level to earth. Then for many years, these components would stay perfectly aligned, continuously running at optimum speeds, and producing superior quality board. Unfortunately, this is not a perfect world! In the real world, corrugating equipment falls prey to many of the same causes of misalignment that effect other industrial machinery and process lines, such as:

Normal operation

Routine corrugator inspections are key to identifying potential issues

- Vibration

- Deterioration of components over time

- Corrosion of floor and/or building settlement

- Process upsets or crashes

Routine Maintenance

- Replacement of rolls, bearings, etc.

Component upgrades or additions

- Removal or installation of components

Accidental damage

- Crashes

- Bearing or coupling failures

- Fork truck strikes

Even though many of the causes of misalignment are inevitable, there are measures you can take that will reduce the impact on both process and product. Routine maintenance inspections done by both your in-house maintenance team and an outside alignment vendor are key to identifying machinery and alignment issues well before they can become catastrophic and extremely costly.

For example, one of the misalignment causes that your in-house maintenance team can be on the lookout for, include changes in the foundation condition, such as broken grout, loose shim, cracks or separation. Any of these are a good indication that your building is settling or the equipment is shifting.

In addition to your in-house team inspections, it is highly recommended that a Corrugator Inspection and Tune-up Alignment Plan be implemented. Corrugator inspections and/or alignment tune-ups are typically completed every two years by an alignment vendor and are most often implemented after a thorough corrugator alignment project has been completed. Each inspection and/or tune-up provides a historical record of the machine’s alignment condition and serves as a means to identify components that have shifted or have specific hardware concerns. Typically, a corrugator inspection uncovers issues such as:

- Worn hardware

- Bad bearings or worn journals

- Equipment shift due to building settlement

- Equipment shift due to strikes

In a perfect world there would be no need to regularly inspect your corrugating line – but in the real world, being proactive with the maintenance of your equipment is the wisest and most cost-effective approach. If you would like to discuss creating a Corrugator Inspection and Tune-up Alignment Plan for your facility, please contact us or reach out to the OASIS Service Center nearest you.