If you manufacture corrugated products you already know that the challenges are many – and that issues can be very costly. Since we started blogging in 2013, we have provided several educational posts on corrugators including a three-part series on the importance of corrugator alignment, an overview of why routine inspections should not be avoided, and a special piece on eliminating warp.

In this post, we are providing a recap of our previous posts on corrugator alignment in the event you missed any of this valuable information. Additionally, we want to remind you that SuperCorr 2016 is fast approaching! OASIS is honored to be both presenting and exhibiting at this unique event. See below for more on the show.

We thank you for your continued readership and hope you stay tuned to our Industry Blog for more on the innovative world of precision measurement and machine alignment!

Importance of Machine Alignment: Corrugators – Part 1

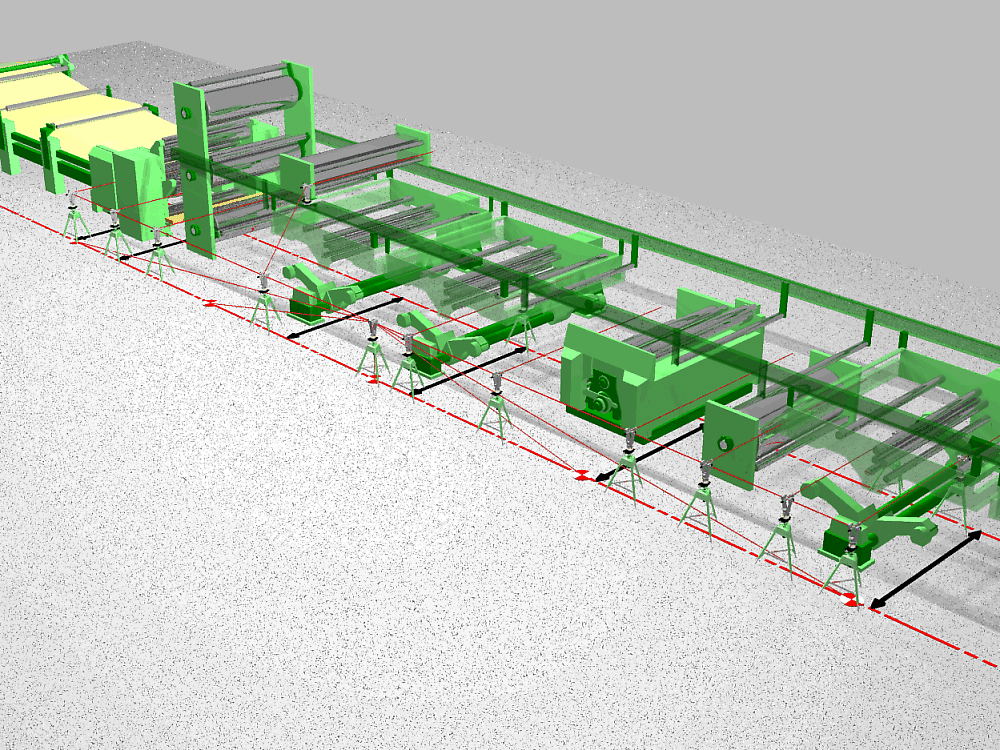

A corrugating client recently contacted OASIS about their desire to increase their machine’s operating speeds, while at the same time improving the quality of their board and reducing the amount of waste they were producing. They needed to find a solution for correcting their delamination and twist warp problems. The solution? A complete corrugator alignment. . .READ FULL POST

Importance of Machine Alignment: Corrugators – Part 2

Precision alignment can help to significantly reduce dreaded warp issues

How do you know if misalignment currently exists within your corrugator? What type of indicators might you come across? This list identifies some of those indicators and how they relate to misalignment . . .READ FULL POST

Importance of Machine Alignment: Corrugators – Part 3

A complete corrugator alignment can be considered an expensive endeavor. However, it is often required due to a lack of alignment checks or corrections as part of a routine maintenance program. Comparing this to automobile ownership, there are standard maintenance milestones that are required to maintain optimum performance (i.e. oil changes, tire rotations and alignment, tune-ups, belt replacements, etc.). Ignoring these milestones will . . .READ FULL POST

Routine Corrugator Inspections Key to Identifying Potential Issues

In a perfect world, all components within your corrugating line would be installed on centerline, perpendicular (square) to the centerline, and level to earth. Then for many years, these components would stay perfectly aligned, continuously running at optimum speeds, and producing superior quality board. Unfortunately, this is not a perfect world! In the real world, corrugating equipment falls prey to many of the same causes of misalignment that effect other industrial machinery and process lines, such as . . .READ FULL POST

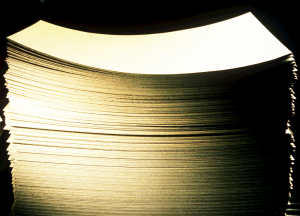

Why is Eliminating Warp Still Such a Mystery?

If you manufacture corrugated paperboard, eliminating warp is a familiar challenge. There are a number of factors that contribute to warp and an equal number of techniques for reducing it, but the ability to completely eradicate warp still remains a mystery. In this post, we provide an overview of paperboard warp and provide several options for decreasing its occurrence . . .READ FULL POST

Packaging Company Sees Impressive Results after Corrugator Realignment

One of the largest packaging facilities in the Midwest requested an alignment survey of the double backer through the wet end of their corrugator. During the initial survey, OASIS found significant misalignment conditions. After a complete realignment of the machine, this facility has seen a marked improvement. . .READ FULL POST

If you are interested in improving the efficiency of your corrugating line and would like to schedule a meeting with an OASIS representative, please contact us. And, do not forget to subscribe to our Industry Blog for regular updates on precision measurement and alignment technologies, industry updates and more.